Where to use the Electrex products and solutions

ENERGY EFFICIENCY

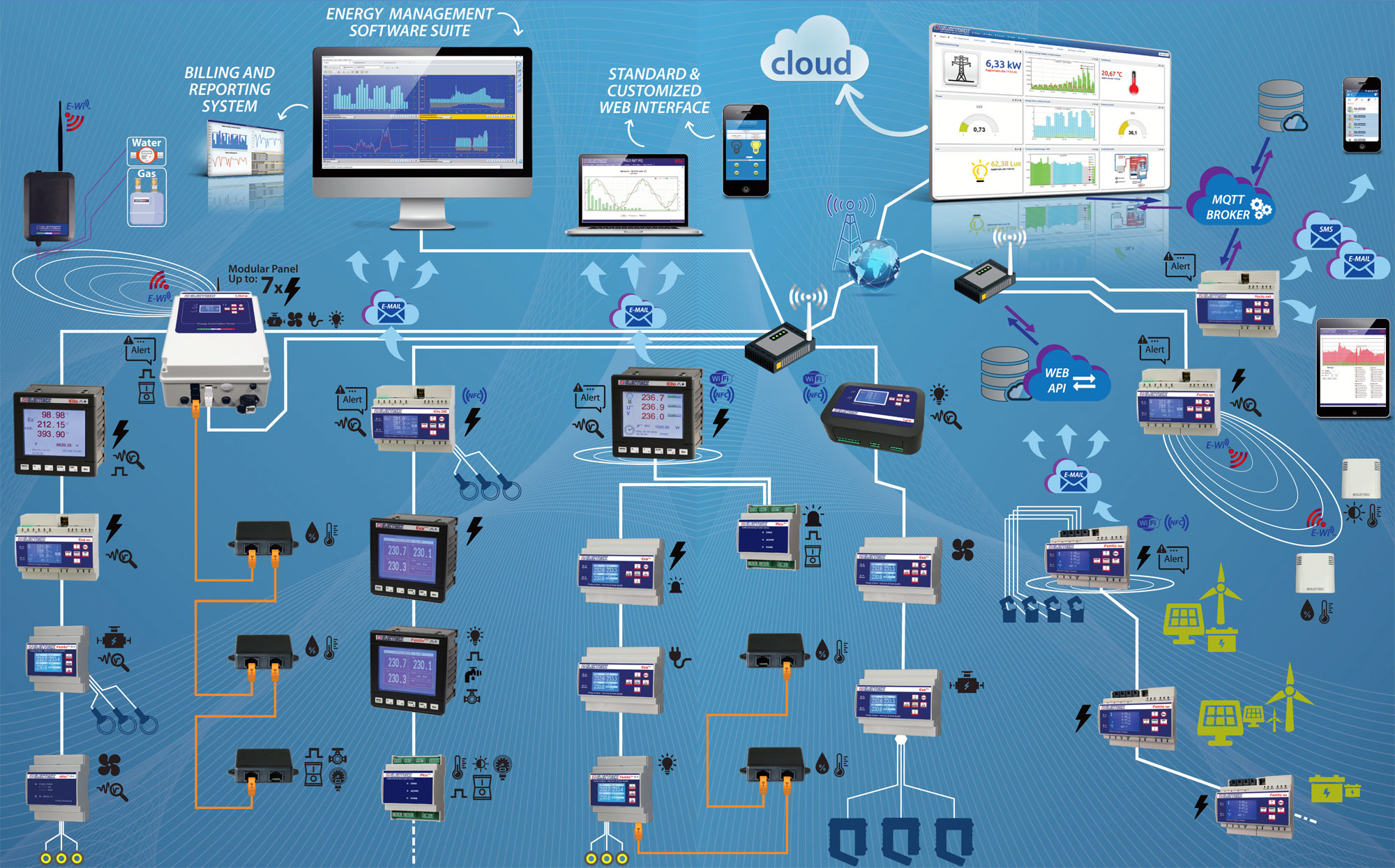

The Electrex monitoring and management solutions are used in the Energy Efficiency and Energy Automation applications, in the industrial, commercial, residential, public buildings and renewable energy systems (PV, Wind, Batteries, etc.) and allow a return on investment in a short time. They are the ideal solution for energy audits, continuous monitoring (e.g. ISO 50001) and for energy efficiency projects (e.g. EU Directive 2018/2002 and White Certificates or Energy Efficiency Certificates, Directive 2018/844 / EU – the Energy Performance of Buildings Directive and LEED certification).

Electrex systems are modular and can expand over time thanks to the multiple connection possibilities of the devices: Ethernet, Wi-Fi, RS485, E-Wi, WM-Bus, ExpBus, NFC.

With a single system (with data synchronization) it is possible to monitor and manage all the energy vectors (electricity, gas, water, etc.), the environmental parameters related to them (temperature, humidity, luminosity, CO2, etc.) the process parameters (compressed air, calories, level, status, etc.), and the operating times.

POWER QUALITY

Power quality is already one of the main concerns for electrical systems and PQ analyzers should be included by default in your panels / auditing services. From one side, we have today a higher equipment sensitivity and from the other side the same modern equipment is a source of PQ problems. As a result they fail more often.

Reliability and consistency of electricity supply is one of the most important conditions for the activities of industrial and service companies. Problems originating from poor Power Quality include interruptions, dips or harmonic pollution. Therefore the loads connected to a network with such problems will fail, have a short lifetime and the efficiency of the system will decrease.

Power Quality problems are a major source of:

- Unexpected Business Downtime

- Equipment Malfunction and Damage.

A Power quality monitoring solution sized according to your needs serves to identify them and intervene accordingly where the disturbance is located.

RENEWABLE SOURCES AND DIRECT CURRENT SYSTEMS

The growing role of DC systems will also drive the demand for monitoring and controlling solutions. In particular, Electrex sees opportunities for direct current measurement systems in electric vehicle charging stations, in power generation systems (renewables), data centers / server farms, microgrids and in peer-to-peer energy sharing.

ENERGY COST CENTERS ANALYSIS

Measurement-based energy audits represent a great opportunity for companies. The usefulness of these tools is represented by the possibility of identifying the most relevant energy cost centers in their sites and therefore of increasing their energy efficiency through targeted investments.

ENERGY AUTOMATION

With Energy Automation in Electrex we mean the interconnection of machines and systems within company processes, with the aim of managing them better thanks to the Energy Automation functions.

In the Electrex devices of the Net series it is possible to implement these Energy Automation functions by ordering the Net upgrade activation codes (PUKs) in order to add to the instruments the “energy PLC” functionality.

REMOTE MONITORING AND REMOTE MANAGEMENT

The Electrex monitoring and management systems can help systems and processes to remain operational by continuously monitoring of machinery (digital twin) and the possibility of having a remote overview of the plants. Data from machines and systems can be collected in real-time, analyzed and managed 24 hours a day, 7 days a week.

The sensors with which machines and systems can be equipped and the Electrex devices that allow connection to the LAN / Internet network provide a continuous flow of data. This allows you to remotely monitor the condition of the machinery and to know immediately when one of them is malfunctioning or starts to show anomalies. In case of malfunctions notifications (e-mails, pop-ups, Telegram messages, SMS, etc.), sent directly from the system, will notify the maintenance team.

PREDICTIVE MAINTENANCE AND ANOMALIES CONTROL

This is a management modality in which, thanks to the continuous acquisition of data, it is possible to manage maintenance knowing the real operating conditions of the machine. In this way, interventions are no longer at regular intervals, but based on the actual operating conditions and before the occurrence of failures, significantly lowering repair costs.

To know the state of health of the machine, it is necessary to monitor it by using sensors that provide parameters related to the operation of the machine (e.g. vibrations, electrical anomalies, noise, etc.).

INTERCONNECTED MACHINES

With modest investments and low invasiveness, new machines (OEM) can be built or existing ones can be revamped by integrating new technologies with existing systems in order to:

- Quantify and manage energy to reduce its impact on the final cost of the product

- Optimize production management by remotely controlling the machines via mobile devices (tablet, smart-phone, etc.)

Better manage the use of energy - Get real time notifications in order to avoid down times

- Apply predictive maintenance policies

Through the numerous functions that can be integrated into the NET series it is possible to:

- Measure and Monitor energy of multiple parts / systems of a building Save

- Integrate sensors, machine status, alarms and counting signals / impulses

- Make calculations in relation to the pieces produced

- Represent all the quantities on an interactive display

- Log data and events

DIGITIZATION AND INTERCONNECTION

The digitization of business processes and the tools for remote collaboration between management, production and service providers / maintainers, improve the resilience of companies allowing them to react quickly to uncertainties and prepare themselves to manage new scenarios.

The Electrex IoE platform allows you to privilege the use of digital, amplifying remote management methods and interconnection between plants and systems:

- Industry 4.0 production plants

- HVAC (Heating, Ventilation and Air Conditioning) systems

- ERP (Enterprise Resource Planning)

- MES (Manufacturing Execution System)

- BI (Business Intelligence)

- BIM (Building Information Modeling)

- and more …

IOE – INTERNET OF ENERGY

With the acronym IoE (Internet of Energy) in Electrex we mean the application of the IoT to the world of energy and energy efficiency.

Electrex IoE is a digital platform through which it is possible to control and manage plants and buildings, which combines the aspects of Monitoring and Energy Automation, in which Electrex has been the market leader for years, with the possibility of interacting in real time with different devices using the possibilities offered by IoT systems.

ENVIRONMENTAL AND PROCESS PARAMETERS

With a single system it is possible to monitor and manage all the environmental parameters (temperature, humidity, brightness, CO2, etc.) and the process parameters (compressed air, calories, level, status, etc.) which are always strictly correlated with energy consumption.

AIR QUALITY

The Electrex Sensing Solutions allow you to monitor key environmental parameters such as Particle / Particulate Material / Fine Dust (PM1.0, PM2.5, PM4, PM10), Volatile Organic Compounds (VOC), CO2, temperature, humidity and differential air pressure with the ability to create notifications / alarms, control HVAC (Heating, Ventilation and Air Conditioning) systems and managing energy consumption in a sustainable way.