Many applications now see benefits in switching to using DC power

Since it is easier to use, for more than a hundred years Alternate Current (AC) has been the default option for any energy distribution system.

In recent years instead, what companies and building owners are discovering is that Direct Current (DC) can greatly improve efficiency in many applications.

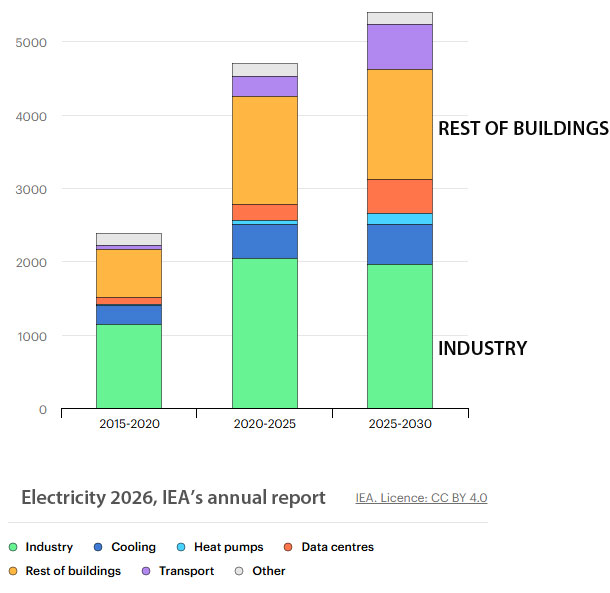

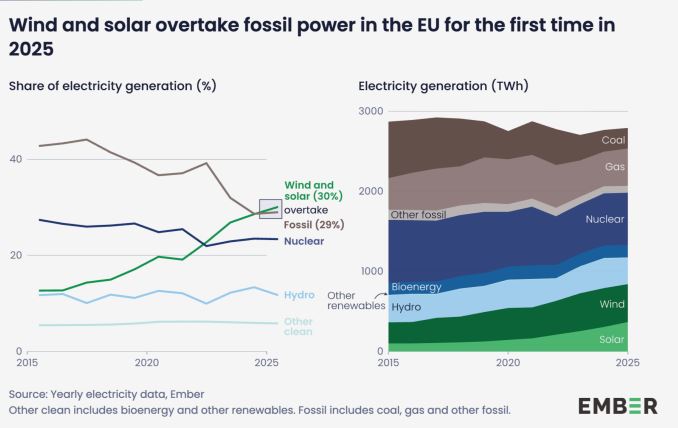

One of the main reasons is the critical mass that DC has reached due to the energy transition initiatives. Energy Transition is the shift to a low carbon, environmentally friendly, reliable, and affordable energy supply.

Especially the needs for new, efficient energy conversion technology and improved battery chemistry are growing rapidly.

Some of the main DC system benefits are:

- Reduction of conversion losses.

- Improved integration of renewable energies and DC sources.

- Use of recovery energy.

- Savings from simpler and more compact systems design.

- Better power quality and system reliability.

DC energy measurement applications

The growing role of DC systems will also drive the demand for monitoring and controlling solutions.

Electrex sees opportunities for direct current measurement in electric vehicle charging stations, in power generation systems (renewables), data centers / server farms, microgrids and in peer-to-peer energy sharing.

Contact me to schedule a call! I will be glad to answer any questions you may have.

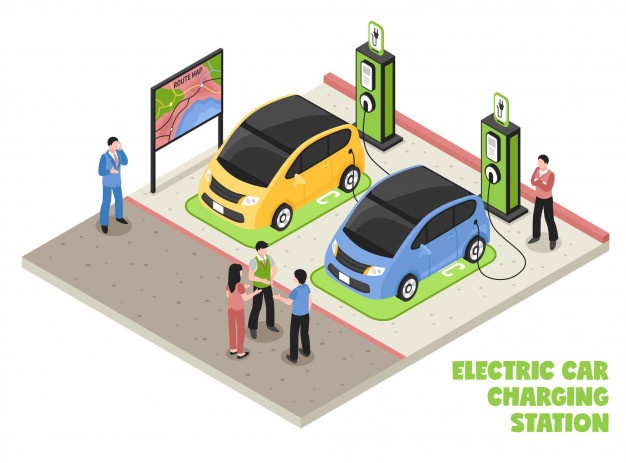

Electric vehicle charging stations

Electric vehicle charging stations

Electric vehicle charging will become a massive energy trading market, resulting in the need for accurate energy billing.

In many cases the energy measurement of standard EV chargers is calculated on the AC side. This means that the energy lost in the AC-DC conversion is not measured. So the end customer is being charged for more energy than he is effectively using.

Governments are introducing normatives to regulate this sector but the energy conversion and distribution losses still remain.

For example the new EU regulations oblige energy suppliers to invoice the customer only for the energy transferred to the EV, with the consequence of leaving the energy conversion and distribution losses to the supplier.

There is a clear need for accurate, DC side billing considering the new fast and ultra-fast EV chargers where energy is transmitted in DC and when connected directly to the vehicle battery.

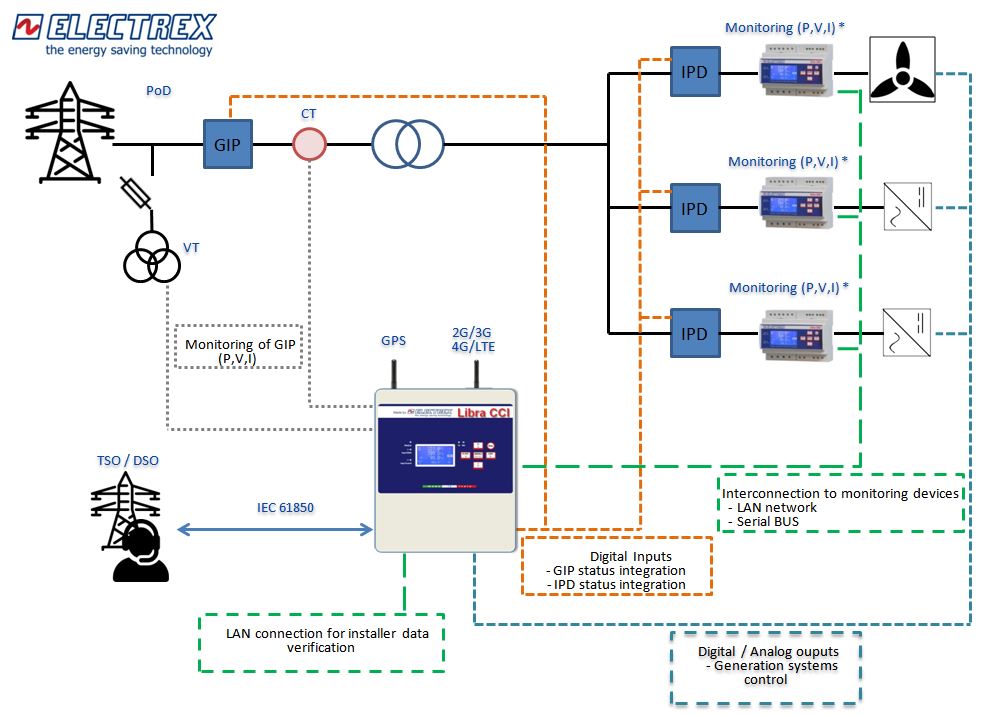

DC distribution – DC Microgrids

A microgrid is a self-sufficient energy system that serves a discrete geographic footprint, such as a college campus, hospital complex, business center, or neighborhood.

With the widespread use of renewable energy generators (solar panels, wind turbines, etc.), generator sets and energy storage buildings can even become totally self-sufficient (but still supported / connected to the grid).

Up to 50% of a building’s electrical loads run on direct current. Currently, every electronic device must convert alternating current into direct current, and up to 20% of the energy is lost in the process, with an estimated total saving of up to 28% compared to traditional alternating current distribution.

Efficiency can be generated by converting AC current to DC all at once and directing DC directly to appliances that need it, such as LED lights and computers.

Interest in DC microgrids is growing rapidly, and consequently also the need to measure and monitor DC loads.

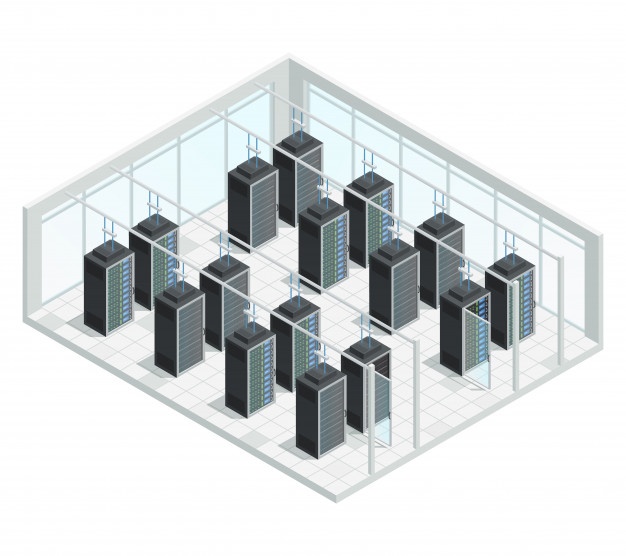

DC data-centers / server farms

In modern server farms, integration with renewable energy today is much easier and more efficient. This allows to extend the DC part of the system and to reduce the conversion (AC/DC) steps.

Accurate measurement of DC power is gaining interest as many operators share the same hardware infrastructure with multiple customers.

Shifting to the more measurable approach of charging customers based on use of energy is a necessity for being more efficient and competitive.

The two most common charging methods for the use of energy are:

- per whip: fixed rate for each socket

- metered energy: socket equipped with a meter and charging of the kWh actually consumed

How DC power and energy is measured

Modern energy meters, alternating or direct current are built in compliance with international standards and are all classified according to the number of pulses per kWh and the accuracy class.

While the measurement of voltage in DC systems is done mostly the same way in all the types of devices, current measurement offers more alternatives, including direct and indirect modality.

Main methods for current measurement:

DIRECT – Shunt Resistance

Shunt measurement is an inexpensive method for measuring current with theoretically an unlimited bandwidth. The current flow is passed through a shunt resistor of known value.

However, this method has some disadvantages. The heat resulting from the Joule effect is proportional to the square of the current. This will cause not only losses in terms of efficiency, but a self-heating that will change the resistive value of the shunt itself resulting in a decrease of accuracy. In order to limit the self-heating effect, a low value resistor is used, which in turn will lower accuracy. Under these conditions, reaching the accuracy required in the lower part of the measuring range can be difficult.

INDIRECT – Magnetic Field Detection

Open Loop Hall Effect Current sensors: Open loop current sensors provide output voltage proportional to measured. The sensor consists of a ring with high magnetic permeability through which the wire of the current to be detected is passed.This type of sensor will provide isolation and high current range while maintaining a relatively low cost. The absolute accuracy generally does not go below 1%.

Open Loop Hall Effect Current sensors: Open loop current sensors provide output voltage proportional to measured. The sensor consists of a ring with high magnetic permeability through which the wire of the current to be detected is passed.This type of sensor will provide isolation and high current range while maintaining a relatively low cost. The absolute accuracy generally does not go below 1%.

Closed Loop Hall Effect Current sensors: This version of the sensor has in addition also a secondary winding on the permeable core. Its linearity is better and there is no core hysteresis with a higher overall thermal drift. A closed-loop configuration offers a higher accuracy, typically lower than 0.5% but are usually bigger, have a higher power consumption as well as a higher price.

Fluxgate: A fluxgate current sensor has basically the same structure as a current sensor with a magnetic balance system, except that it has a magnetic probe coil instead of a Hall element.

It offers good temperature stability and an accuracy of up to 0.1%. However, the complex electronics of the sensor make it an expensive solution with prices 10 times higher than other isolated solutions.

Electrex is your partner for monitoring and controlling DC systems

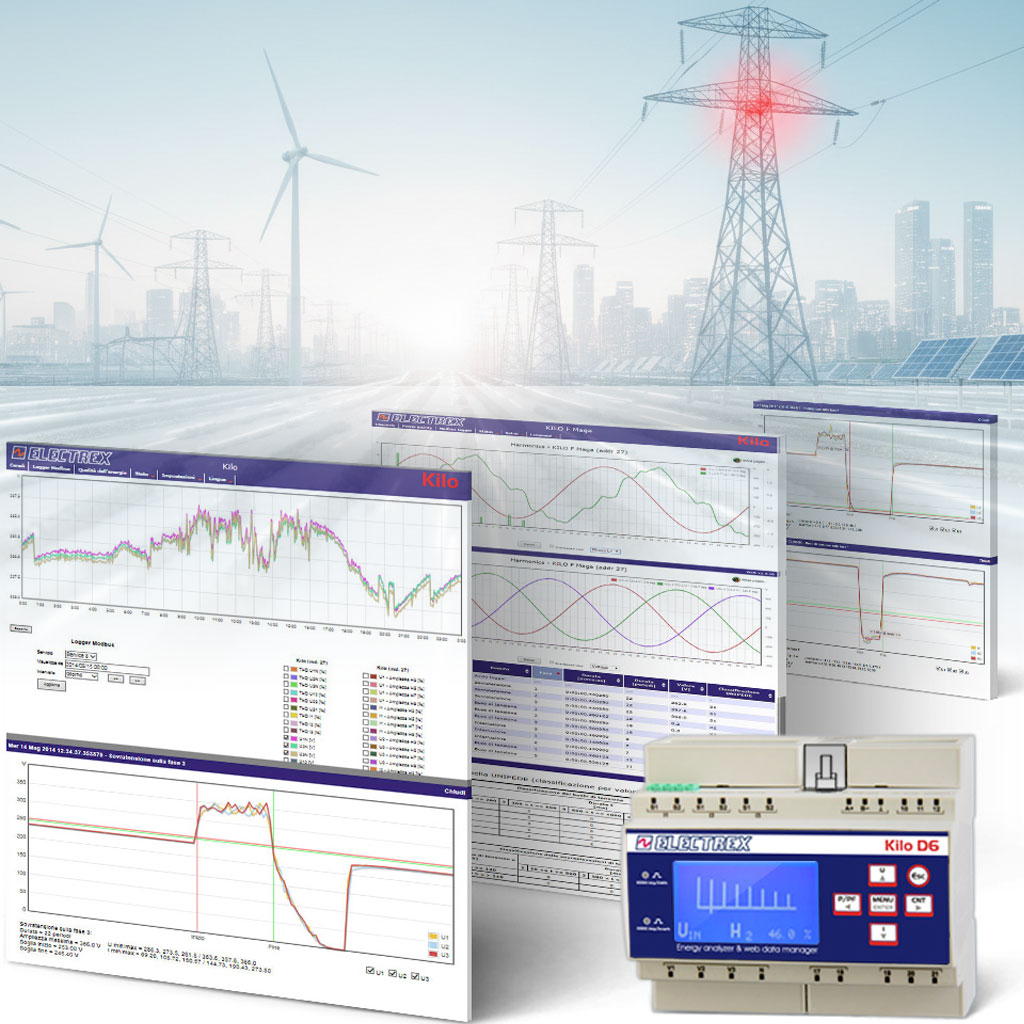

DC applications are not a new challenge for Electrex. We have been manufacturing DC analyzers for more than 28 years, initially using SHUNT resistance method, and have already completed thousands of projects.

This has allowed us to build a solid know-how on the DC systems that has recently been embedded in our new Femto 4Hall D6 series.

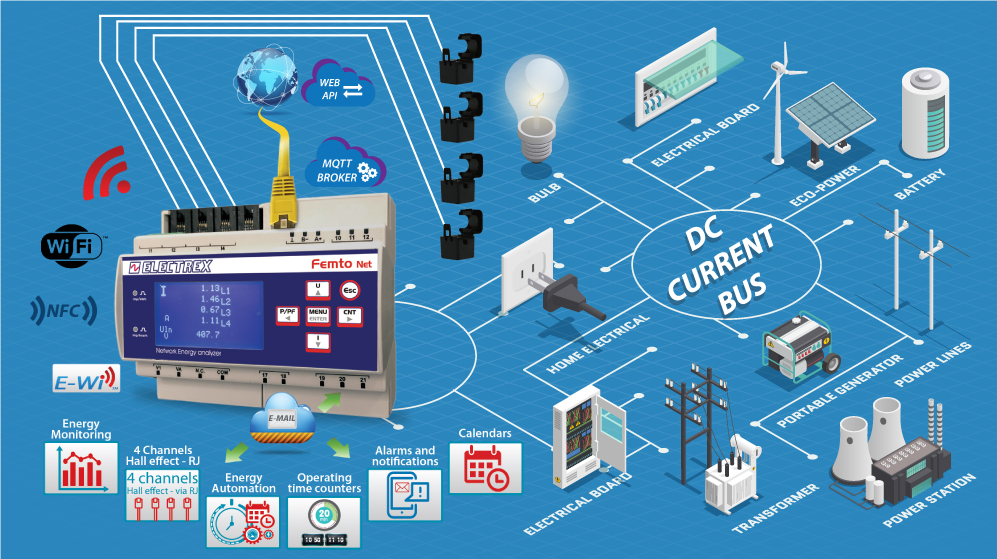

The Femto 4Hall D6 is an DC Energy Analyzer & Web Data Manager with an embedded web server and multiple communication ports (Ethernet, Wi-Fi, RS485, ExpBus, NFC).

Being an ALL-IN-ONE type of device, in addition to the measurement function it also has gateway, datalogger and controller capabilities including an embedded PLC and capable of sending real-time email notifications.

It is equipped with 4 current inputs allowing you to monitor multiple loads with a single device.

The device uses external, Open Loop Hall Effect Current sensors connected via RJ type connectors, directly allowing fast installation and accurate measurements.

The Femto 4Hall D6 can be used as a stand-alone device or interconnected to other units from the same or different series.

The embedded web server used for real time and historical data displaying can be integrated with our software suite and our cloud platform Energy Brain.

Complete monitoring solutions

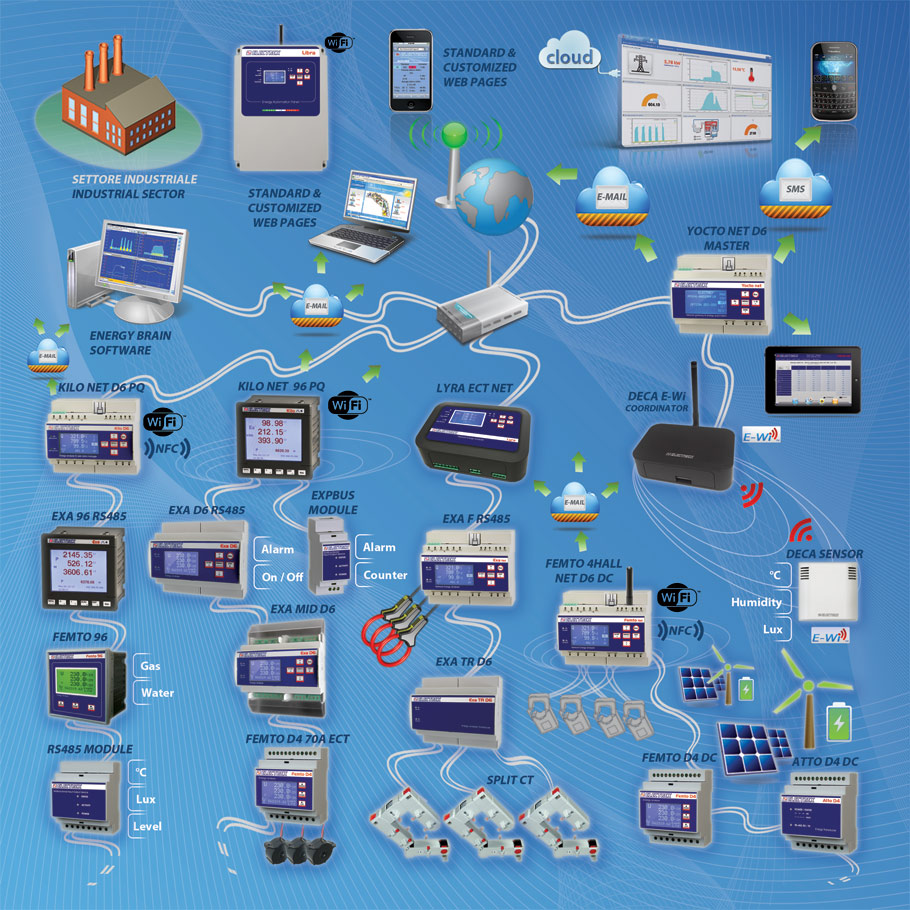

We can offer a complete solution for managing DC and AC systems in any organization.

The Electrex Complete Monitoring networks are the ideal solution for energy audits, continuous monitoring (e.g. ISO 50001) and for energy efficiency projects (e.g. Green / White Certificates or Energy Efficiency Certificates).

The Electrex systems are modular and can expand over time thanks to the many possibilities of connecting the devices (Wi-Fi, RS485, E-Wi, ExpBus, Ethernet, NFC), and of display and management of the data collected.

With a single system, you can keep track of all energy vectors (electricity, gas, water, etc.), of environmental parameters related to them (temperature, humidity, luminosity, CO2, etc.), of process parameters (compressed air , calories, level, status, etc.); measure the operating time of a load / appliance using a single reference clock; manage Energy Automation – Industry 4.0 processes (automate the management of ON/OFF switches, automatic adjustments, remote management, alarms and more) to achieve the main objective: to reduce energy costs and avoid outages.

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 400,000 measuring points and more than 700,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.