Barilla improves the efficiency of its production systems

Barilla improves the efficiency of its production systems

using Electrex energy monitoring and management solutions

Since 2010 Barilla has decided to implement in its Italian plants some important innovations. One of them was to install a system of automatic data collection of energy consumption (electric and thermal) and water. The information would be logged in a single database for data analysis from a central location and also from the individual plants. The same data should be organized for each single production line and by each energy utility / provider used to manage the production processes and cost centers.

The application

In order to minimize the environmental impact the company is investing from many years on optimizing energy consumption. As a result, recently, it has reduced the energy consumption by 10% adopting the latest technological solutions and installing Electrex monitoring and measurement instruments. The Electrex meters measure the consumption of each machine involved in the production process.

In particular, Barilla has intervened on the collection and analysis of data from which it is possible to know in detail the consumption of individual machines and production lines, detecting abnormal absorption or negative trend and on which it is necessary to act also in terms of predictive maintenance . This mode allows the company to determine the most effective solutions, and potential areas of saving.

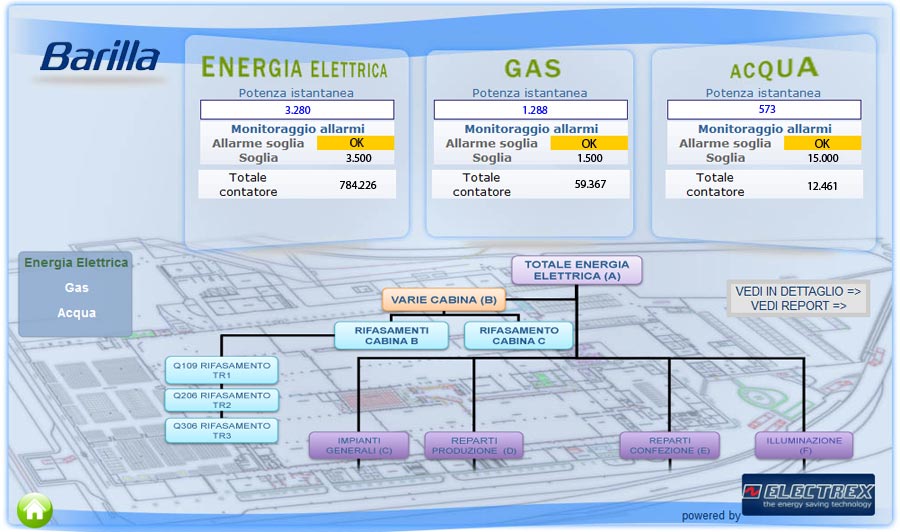

In the production units, Electrex devices has been installed in order to collect data on consumption of electricity (with quality analysis), gas and water. The data collected are transmitted to the local PC over the Ethernet and Modbus RS-485 and then are sent to the central database via the Internet. Access to specific Web pages also allows to the Barilla staff to consult measures on-line using smart phones, tablet PC or any other device with a web browser.

Customer Benefits

The data collected allows to manage information on energy consumption related to the production efficiency.

From the standpoint of energy efficiency, the benefits obtained are different: the adaptation of production sites; the final evaluation in real-time of energy consumption and water consumption for each production line and for individual utilities;the energy rating (Toe – Tons oil equivalent ) and emissions (CO2) in the environment of each production site (and for the total amount of finished product); the historical data and the deviations in equivalent manufacturing situations of the same plant or other plants of the group; identifying energy inefficiencies, wastes, and the evaluation and identification of technical and managerial interventions to reduce consumption, the evaluation of energy saving projects.

The hundreds of measuring devices installed Electrex allow a detailed energy analysis of individual production sites.