Tetra Pak uses the Electrex monitoring networks to reduce CO2 emissions and improve the energy efficiency of its plants.

The first installations of Electrex networks in Tetra Pak production plants date back to 2003 and have gradually developed over the years.

Tetra Pak, which is always attentive to environmental issues in order to reduce the impact on climate change, has set an overall target for all its activities. One of the first objectives was to achieve by 2010 a total 10% reduction of CO2 emissions, compared to 2005.

The goal was reached at the global level.

In the Tetra Pak factory in Modena, for example, the objective was achieved through a continuous improvement in energy efficiency associated with an increased use of electricity from renewable sources.

The optimization of energy efficiency has been achieved thanks to the Electrex monitoring systems through which Tetra Pak makes the energy data collection, analysis of the plant’s energy consumption, divided by individual users and time tariffs, identifies inefficiencies and therefore intervenes in order to optimize the energy demand.

The new strategy for 2020 is to keep emissions same as in 2010 independently by the performance of production that will continue to grow during the same period.

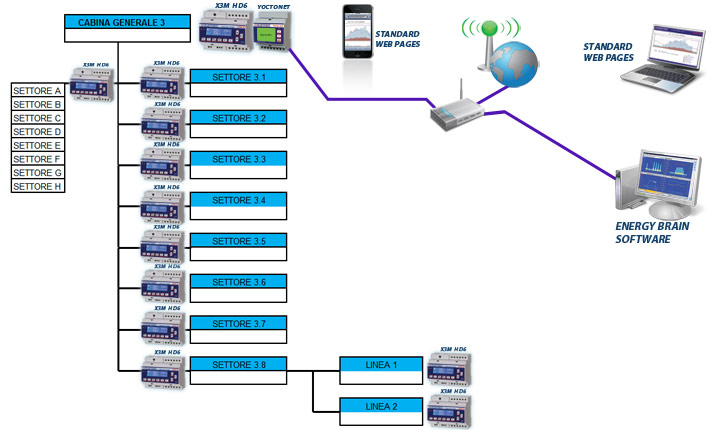

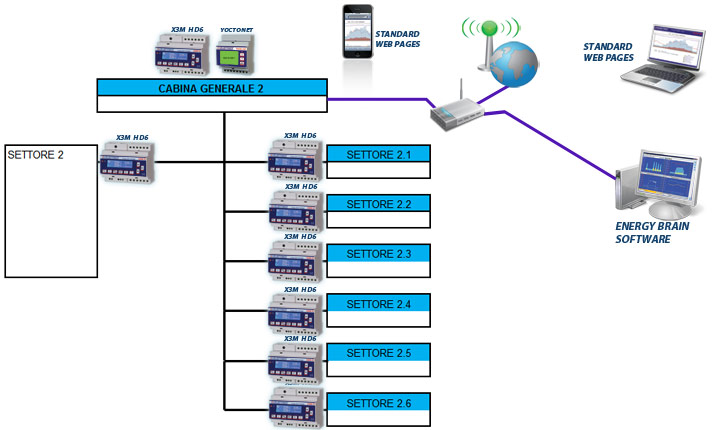

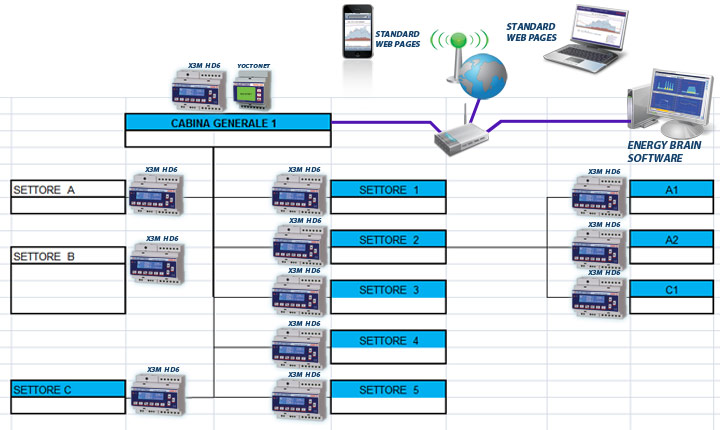

Until 2011, the monitoring system is composed of about fifty Electrex devices distributed in the various buildings that detect, through the Energy Brain software, in addition to electricity and its quality, the consumption of gas of the heating system.

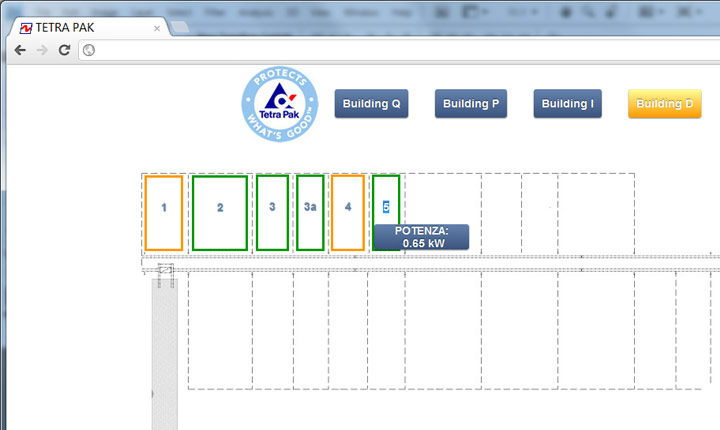

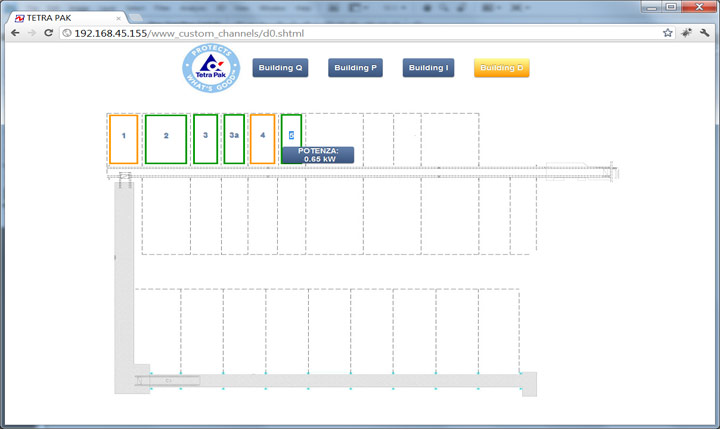

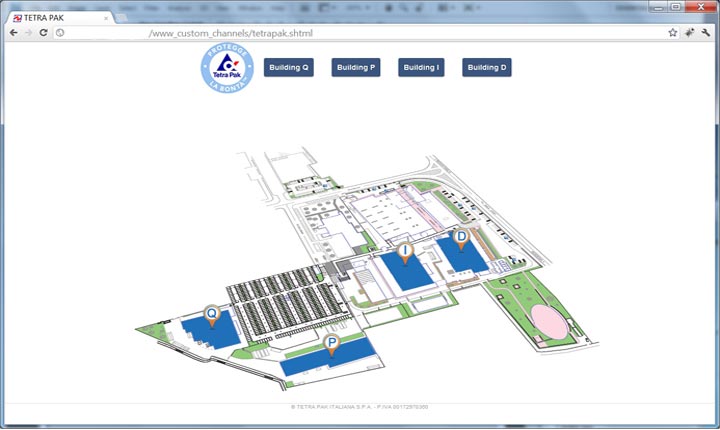

In 2012 a new project on controlling the testing workstations of the machines produced by Tetra Pak started. These machines are arranged in plots, spread over four buildings, connected to the grid and tested.

In this case the aim of Tetra Pak was:

- Automatically detect if in the testing plot any machine is connected to the electrical grid

- Detect if the machine is in stand by or functioning

- Retrieve the energy consumption during the tests and calibration

- Avoid that the machines stay turned on when not necessary

- Eventually turn off automatically all the machines connected when the working shift ends

Using the existing Electrex monitoring system infrastructure around 100 panels with a single Electrex instrument were installed. The panels were connected to various Yocto net network gateways, which were in their turn connected to a Yocto net master. The data were retrieved from the Energy Brain software, already in use in the Tetra pak premises, through the Ethernet and Modbus-RS485 networks.

In order to supervise the plot’s states customized web pages were designed. The Tetra Pak operators and all the people in charge could check the plots and consult the real time measurements on-line from any PC, smart phone or tablet.