..

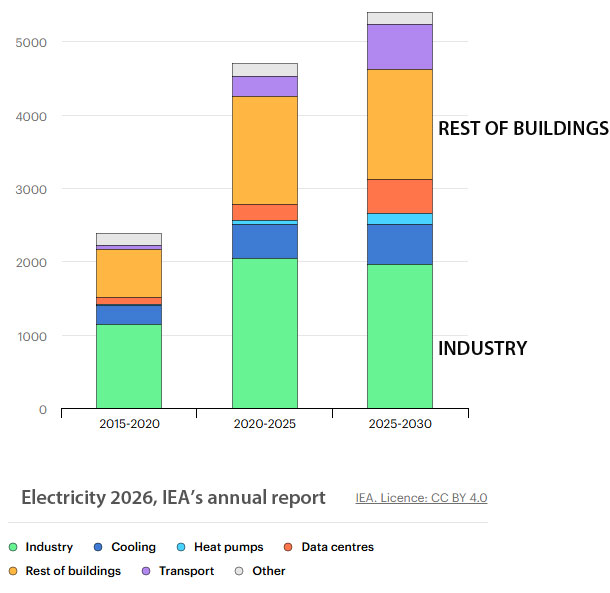

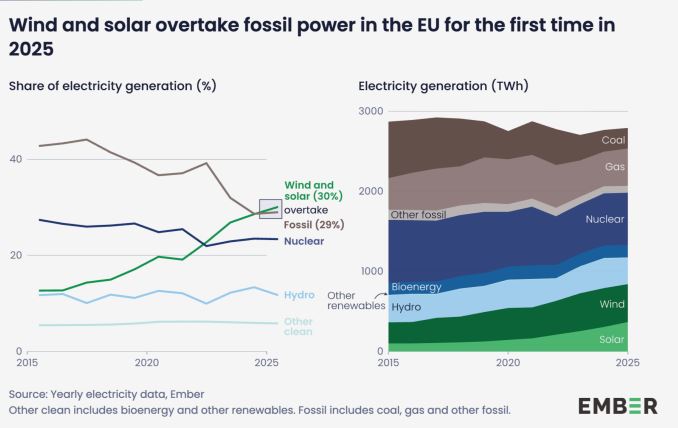

The latest ENTSO-E technical report on instability detection in power-electronics-dominated systems delivers a clear message:

➡️ As power systems become increasingly converter-based, traditional monitoring is no longer sufficient.

Modern instabilities are faster, more complex, and often invisible to basic RMS measurements. Harmonic resonance, control-loop interactions, and phase-angle instabilities are becoming real operational risks.

Power-electronics-driven systems create new instability modes

ENTSO-E highlights that:

-

Conventional synchronous machines are being replaced by converter-based generation and loads

-

System inertia and short-circuit power are decreasing

-

Control loops in power electronics operate very fast, increasing the risk of interaction and instability

Why this matters for PQ analyzers

Instabilities no longer appear only as slow voltage/frequency deviations. They often manifest as:

-

Oscillations

-

Harmonic amplification

-

Phase angle instability

-

Control interaction phenomena (SSTI, resonance)

These cannot be detected with basic meters or low-resolution SCADA.

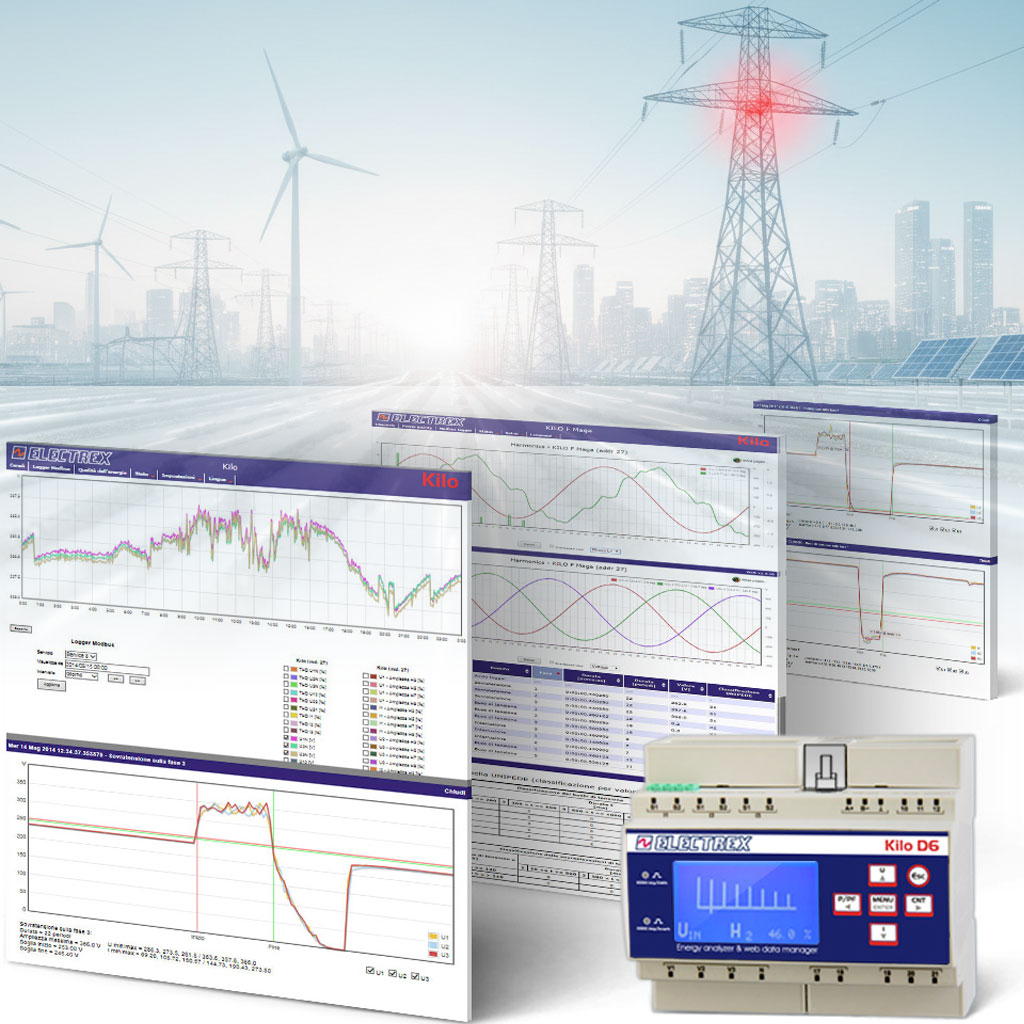

Harmonic resonance and harmonic interaction are critical risks

The report explicitly states that:

-

Increased cable deployment and power electronics shift harmonic resonance frequencies

-

Harmonic resonances can occur close to the fundamental frequency

-

Converter control interactions can amplify specific harmonic orders

-

Harmonic measurement up to the 51st order

-

Voltage, current and phase harmonics

-

Waveform capture and harmonic spectra per phase

This is exactly what ENTSO-E indicates is required to identify, localize, and understand resonance phenomena.

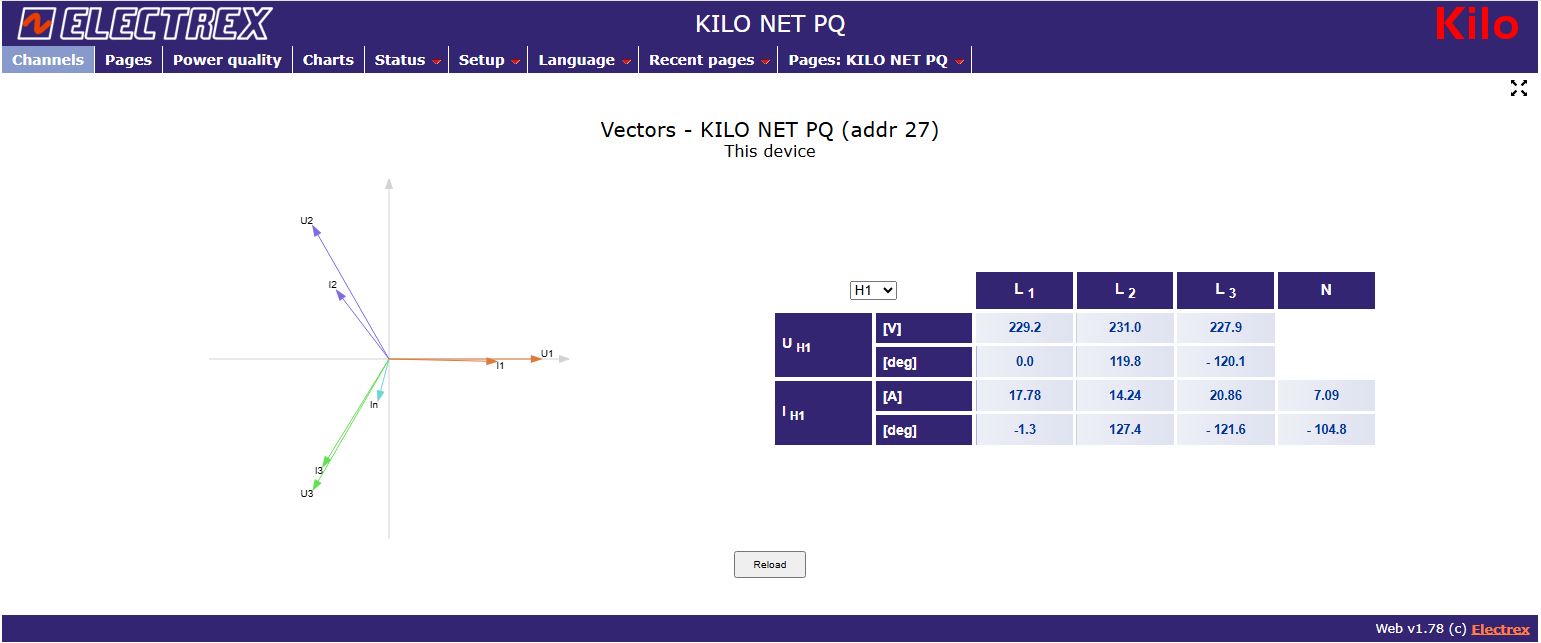

Phasor behavior and phase relationships matter

ENTSO-E stresses the need to understand:

-

Phase angle behavior between voltages and currents

-

Interaction between converters and grid impedance

-

Early signs of instability through vector behavior, not just RMS values

-

Phasor (vector) diagrams of voltage, current, and neutral current

-

Three-phase visualization of magnitude and phase displacement

This enables detection of:

-

Unbalanced operation

-

Phase drift

-

Control-loop induced oscillations

Event-based monitoring instead of periodic reporting

The report underlines that:

-

Instability phenomena are often short-lived and fast

-

Periodic data is insufficient

-

Event-triggered recordings are essential to capture the root cause

-

Power quality event detection

-

Trigger-based waveform and harmonic capture

-

Event classification with charts and graphs (per event or aggregated)

This aligns perfectly with ENTSO-E’s recommendation for event-driven observability.

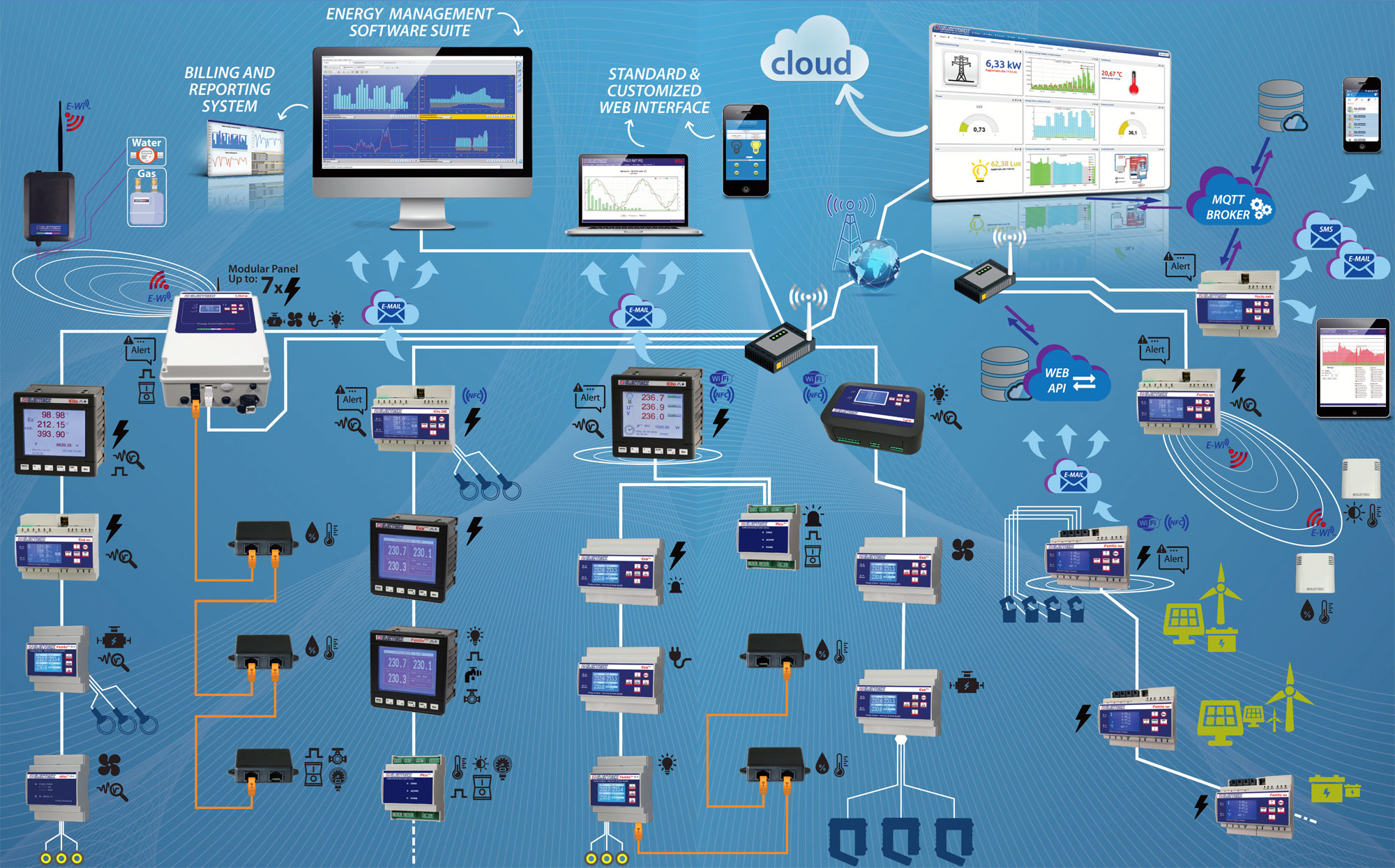

Need for observability at distribution and plant level

ENTSO-E clearly states that instability detection:

-

Cannot rely only on TSO-level measurements

-

Requires visibility closer to converters, plants, and loads

-

Benefits from distributed monitoring and aggregation

-

Distributed PQ analyzers at plant, feeder, or load level

-

Data aggregation via gateways / EMS

-

Integration of PQ, energy, process, and environmental data

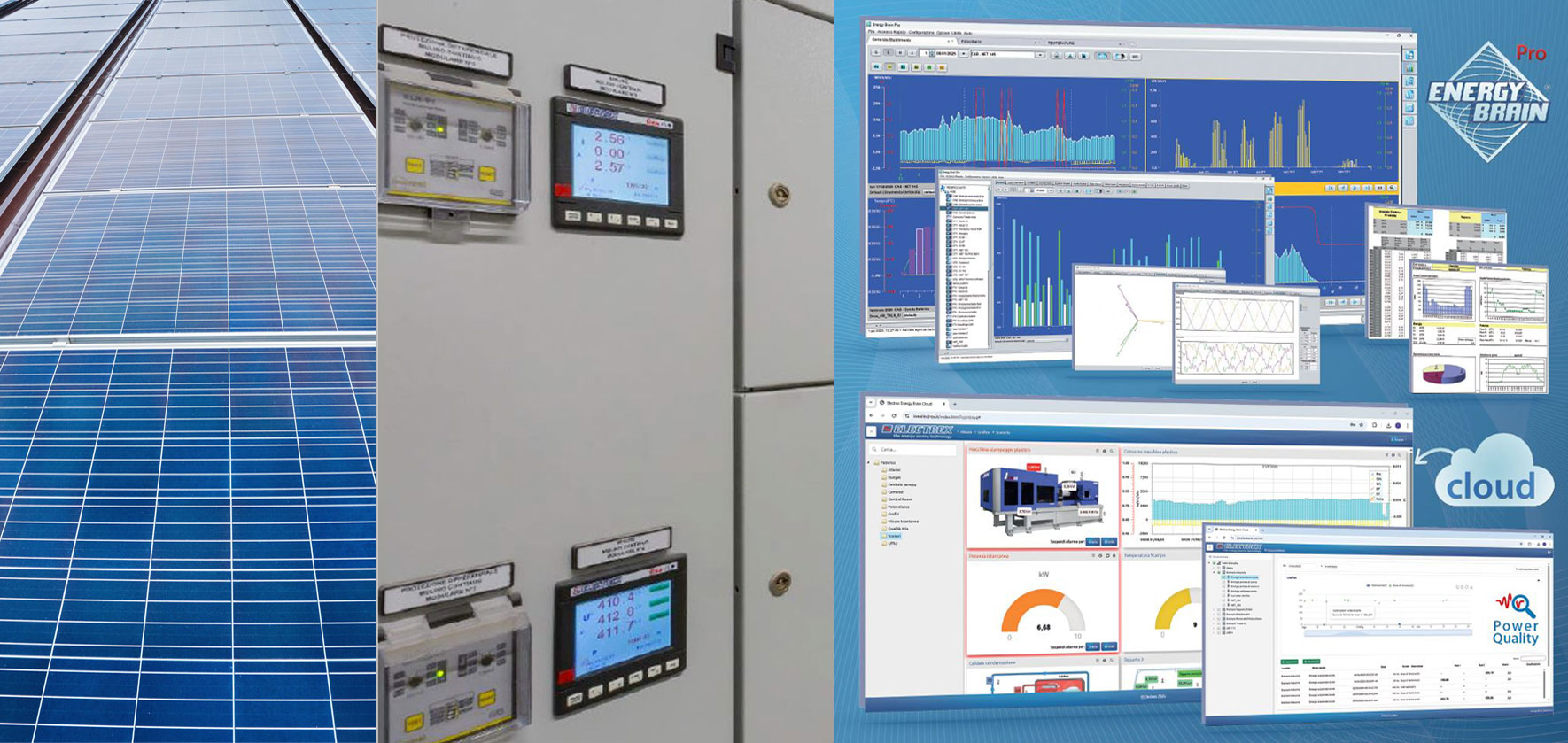

How Electrex Monitoring & Control Solutions Address These Needs

Putting it all together, Electrex addresses the ENTSO-E recommendations across three layers:

1️⃣ Deep electrical observability (your PQ analyzers)

-

Phasor diagrams → phase stability & interaction visibility

-

Harmonics up to 51st order → resonance & converter interaction detection

-

Waveforms → transient and control-loop behavior

-

Event-triggered recordings → root-cause analysis

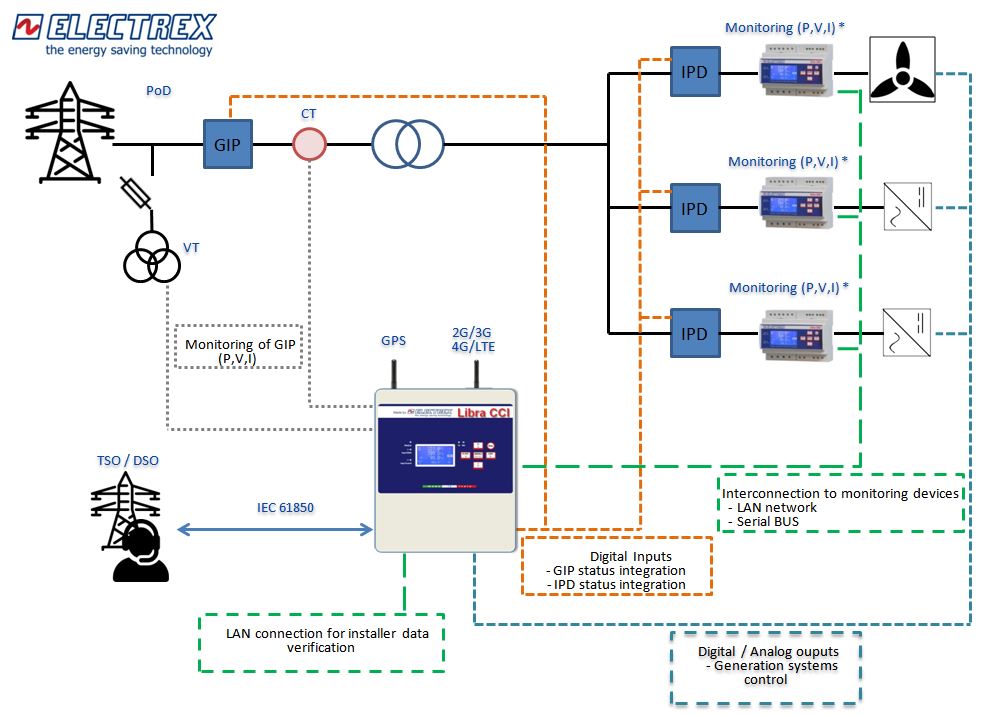

2️⃣ Data aggregation & system-level visibility

-

Multi-device aggregation (generation, loads, PQ, environment)

-

Unified view of electrical + operational context

-

Readiness for system-wide instability analysis

3️⃣ Control & mitigation readiness

-

Integration with controllers (e.g. Libra CCI, PLC logic)

-

Ability to correlate PQ events with control actions

-

Foundation for automated mitigation strategies (curtailment, control tuning, alarms)

In short: Electrex does not just detect problems — it enables understanding and action.

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 560,000 measuring points and more than 1,020,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.