The impact of COVID-19

Industry, commercial and services sectors are based on processes that must be constantly monitored to ensure that their activities are always running, reliable and efficient.

Just a few months ago these activities were carried out partly automatically and partly by expert technicians who, thanks to their skills, were able to recognize failures or inefficiencies.

The COVID-19 emergency has significantly changed habits by imposing barriers and, when possible, the use of remote working, causing significant difficulties in process control and maintenance management.

In this scenario it is critical to accelerate the adoption of digital control procedures and of remote and predictive maintenance.

So it is necessary to create the conditions that allow to operate remotely and intervene only when necessary, avoiding costs for unnecessary travels and optimizing the company’s operations.

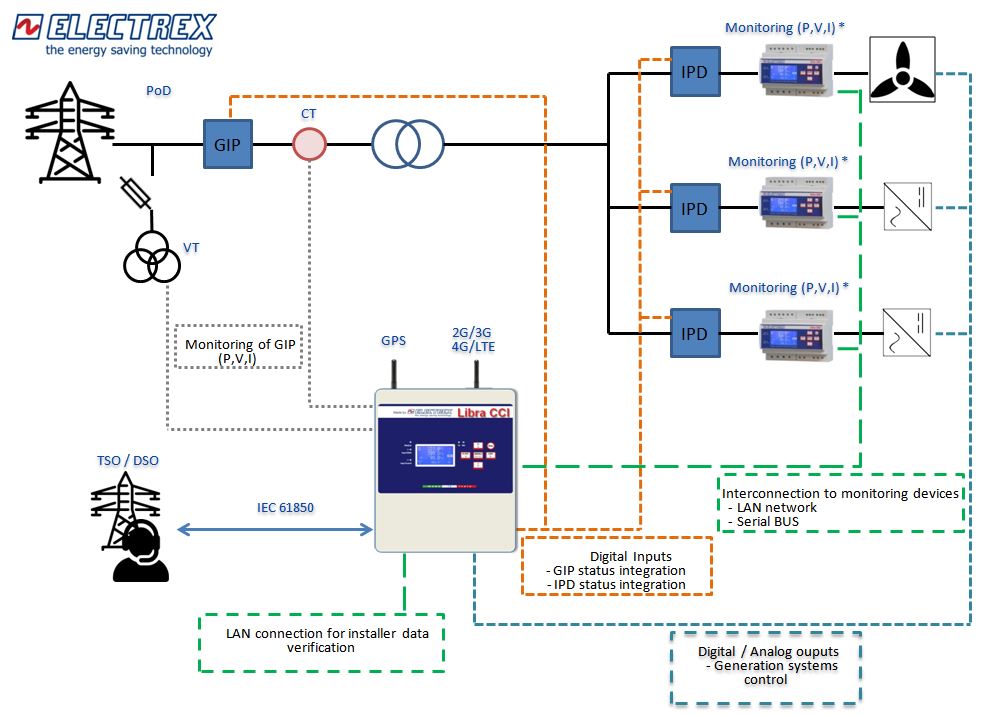

The technologies made available by the Electrex Internet of Energy (IoE) platform make the difference by promoting remote and predictive maintenance, the use of digital and interconnection between systems in the company.

Remote maintenance with Electrex IoE

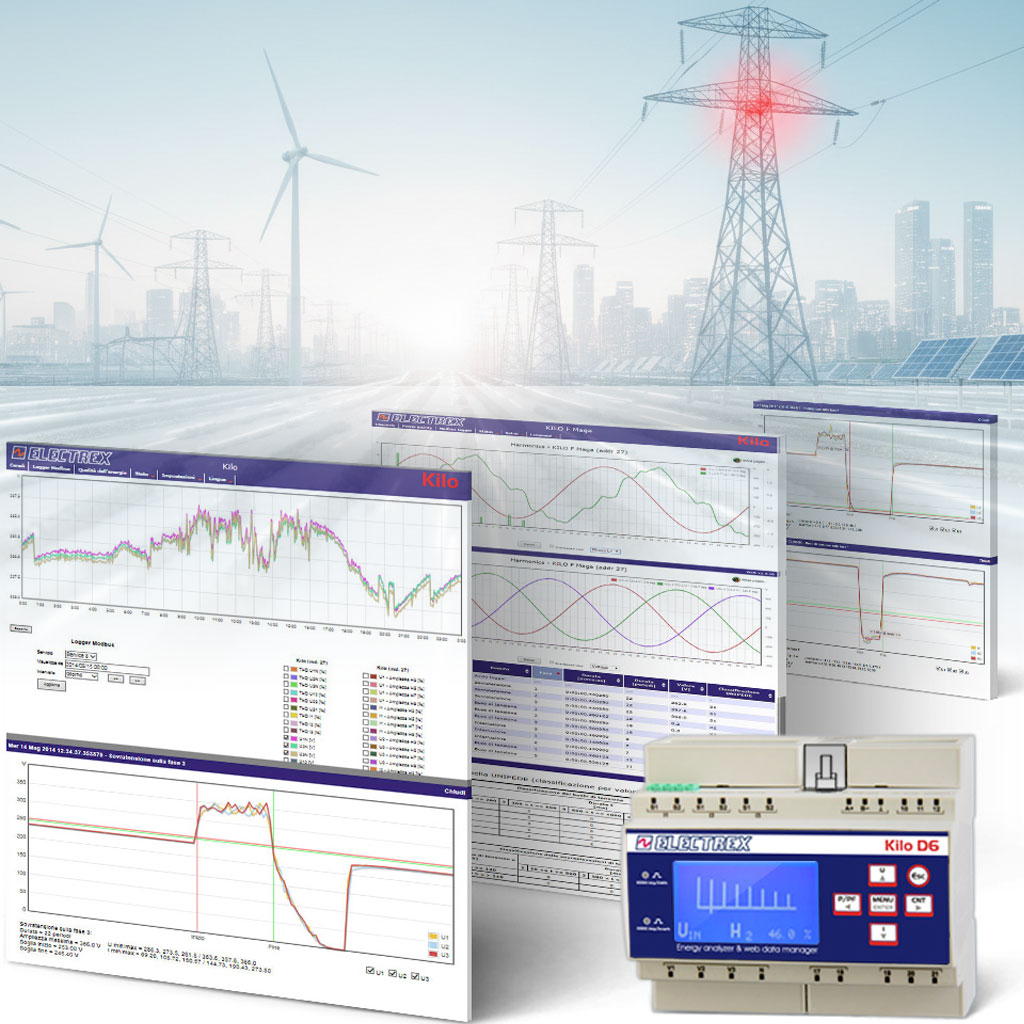

The energy, environmental or other data gathered from Electrex IoE can be used in order to understand the performance of equipment/system. The exchange of data and implementation of analytics allows for condition-based monitoring and editing of energy profiles for each component. This new approach utilize measurements on the actual equipment in combination with measurement of energy and process performance, measured by other devices, to trigger equipment maintenance.

The first way Electrex IoE solutions can help plants and processes stay operational is through continuous remote monitoring of machinery and the ability to have a plant overview (Digital Twin).

The data coming from machines and plants can be collected in real time, analyzed and managed 24 hours a day, 7 days a week. The sensors, with which machines and systems can be equipped, and the Electrex devices that allow connection to the LAN / Internet network provide a continuous flow of data.

This allows to remotely monitor the condition of the machinery and to know immediately when one of them is malfunctioning or starts to show anomalies.

Notifications like E-mails, pop-ups, Telegram messages, SMS, etc., sent directly from the system, will notify the maintenance workers in case of malfunctions.

It is therefore possible to perform further checks remotely, operate commands (also remotely) and only in case of actual need contact the maintenance staff to perform or plan the operations necessary to restart the machine.

Contact me to schedule a call! I will be glad to answer any questions you may have.

Digitization and interconnection

Digitization and interconnection

The digitalization of business processes and the tools for remote collaboration between management, production and maintainers, improve the resilience of companies by allowing them to react quickly to uncertainties and manage new scenarios.

The Electrex IoE platform supports switching to digital processes, enhancing remote management methods and interconnection between systems and machinery:

- Industry 4.0 production plants

- HVAC (Heating, Ventilation and Air Conditioning) systems

- ERP (Enterprise Resource Planning)

- MES (Manufacturing Execution System)

- BI (Business Intelligence)

- BIM (Building Information Modeling)

- and more …

Interconnected Machines

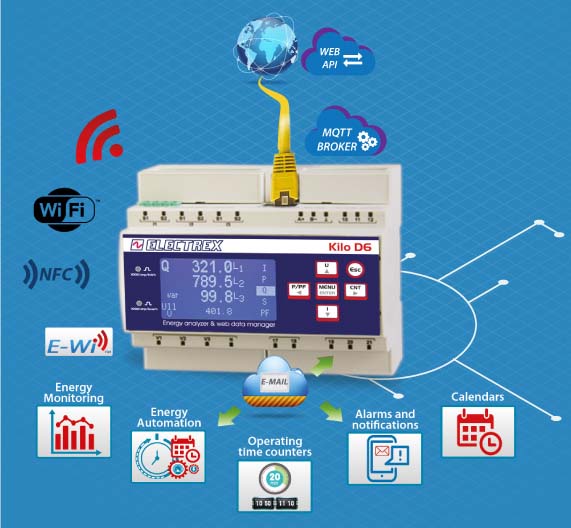

The Electrex devices of the NET series are equipped with an embedded web server and multiple communication ports and protocols.

Through the numerous functions that can be integrated into the NET series it is possible to:

- Measure and Monitor energy of multiple parts / systems of a building

- Integrate sensors, machine status, alarms and counting signals / impulses

- Make calculations in relation to the pieces produced

- Represent all the quantities on an interactive display

- Log data and events

With modest investments and low invasiveness, new machines (OEM) can be built or existing ones can be revamped by integrating new technologies with existing systems in order to:

- Quantify and manage energy to reduce its impact on the final cost of the product

- Optimize production management by remotely controlling the machines via mobile devices (tablet, smart-phone, etc.)

- Better manage the use of energy

- Get real time notifications in order to avoid down times

- Apply predictive maintenance policies

Standard protocols

An intelligent and shared management of data and business processes makes the difference in terms of operational efficiency and decision-making speed.

It is essential that remote management and interconnection are based on protocols that are open, publicly available and internationally recognized (like TCP-IP, HTTP, MQTT, JSON, Web API, etc …).

Electrex IoE solutions use MQTT communication overcoming the constraints imposed by internal IT systems which normally does not allow access to the corporate network from outside.

The Web APIs, on the other hand, simplify the interconnection with business intelligence and management systems.

The advantages of the Electrex IoE platform for companies and their assistance and maintenance teams:

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 425,000 measuring points and more than 750,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.