What is Energy Sobriety?

Energy Sobriety means reducing our energy consumption by changing our consumption styles, uses and behavior.

There are multiple types of sobriety:

- Sobriety of use, which consists in reducing the duration, use or frequency of use of energy-consuming equipment.

- Sobriety of substitution, i.e., replacing an appliance with a less energy-consuming alternative.

- Sobriety of dimension, which means adjusting the use and size of appliances according to our needs.

- Collaborative sobriety, which relies on the sharing of equipment to save energy.

While it is mainly used referring to residential and commercial buildings it will be an important strategy also for industrial manufacturing sites and big buildings looking to meet both profitability and sustainability goals.

Indeed, difficulties with energy procurement and energy costs make energy sobriety and energy efficiency as the key levers for being competitive.

Today, more than ever, the best energy is the energy we save.

Profitability could be improved through a systemic application of simple energy efficiency solutions, and integrating energy sobriety as a default requirement in product and business developments.

It is a matter of consuming less but better. And it leads to increasing the Energy Productivity: the total value gained from using a unit of energy.

Contact me to schedule a call! I will be glad to answer any questions you may have.

How Electrex can support you introduce an Energy Sobriety initiative in your organization

Energy Sobriety differs from Energy Efficiency because it relies on socio-cultural rather than technological levers to optimize consumption.

But in order to have an impact, it should be widespread among all levels of the organization. It means that communication, digitalization and monitoring of the results become very important to achieve that goal.

The notion of sobriety can be divisive within organizations as it can be perceived from both employees and clients as a form of restriction or scarcity. The suggested solution to avoid this is making them more aware.

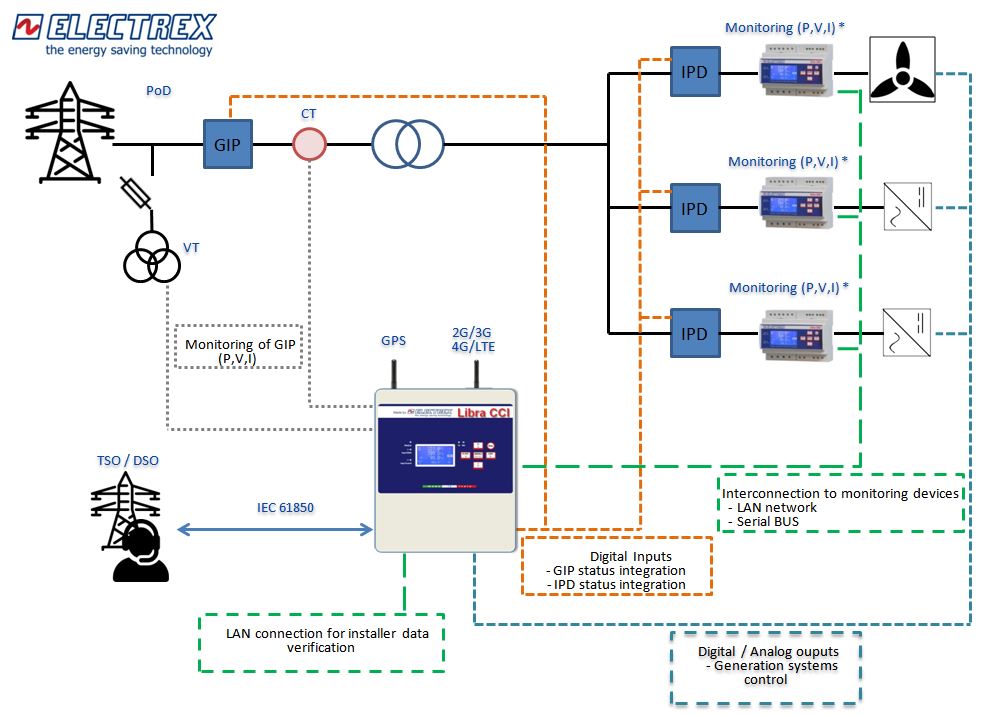

Electrex solutions help you create the interconnection between people, things and systems leading to great advantages in terms of energy consumption reduction, availability of information and interaction between resources.

In order to achieve this, it is necessary to move towards the use of the IoT (Internet of Things) to build effective energy management systems.

With the acronym IoE (Internet of Energy) in Electrex we mean the application of the IoT to the world of energy and energy efficiency.

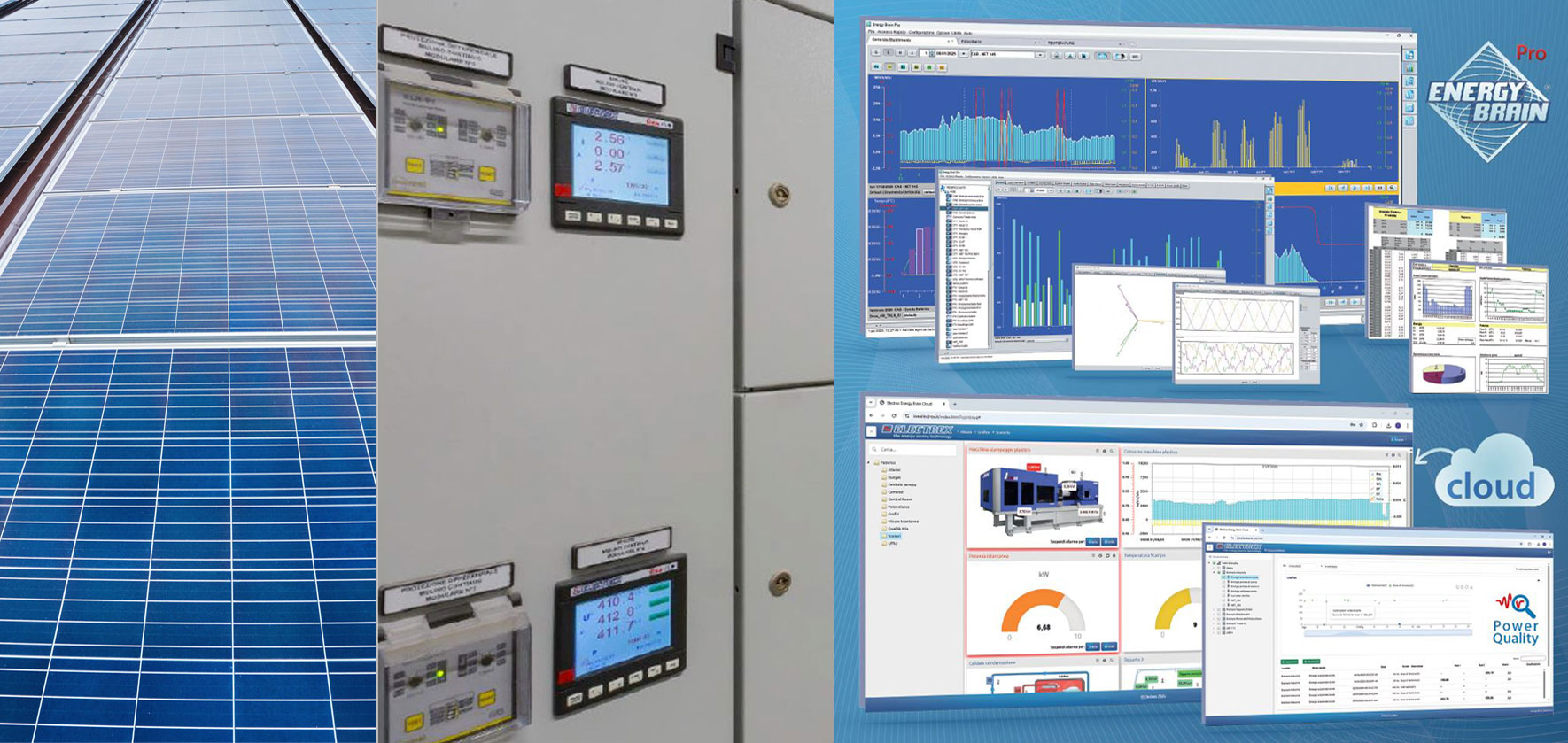

Electrex IoE is a digital platform through which it is possible to control and manage plants and buildings, which combines the aspects of Monitoring and Energy Automation, in which Electrex has been the market leader for years, with the possibility of interacting in real time with different devices using the possibilities offered by IoT systems.

DIGITIZATION AND INTERCONNECTION

The digitization of business processes and the tools for remote collaboration between management, production and service providers / maintainers, improve the resilience of companies allowing them to react quickly to uncertainties and prepare themselves to manage new scenarios.

The Electrex IoE platform allows you to privilege the use of digital, amplifying remote management methods and interconnection between plants and systems.

REMOTE MONITORING AND REMOTE MANAGEMENT

The Electrex monitoring and management systems can help systems and processes to remain operational by continuously monitoring of machinery (digital twin) and the possibility of having a remote overview of the plants. Data from machines and systems can be collected in real-time, analyzed and managed 24 hours a day, 7 days a week.

The sensors with which machines and systems can be equipped and the Electrex devices that allow connection to the LAN / Internet network provide a continuous flow of data. This allows you to remotely monitor the condition of the machinery and to know immediately when one of them is malfunctioning or starts to show anomalies. In case of malfunctions notifications (e-mails, pop-ups, Telegram messages, SMS, etc.), sent directly from the system, will notify the maintenance team.

With modest investments and low invasiveness, new machines (OEM) can be built or existing ones can be revamped by integrating new technologies with existing systems in order to:

-

- Quantify and manage energy to reduce its impact on the final cost of the product

- Optimize production management by remotely controlling the machines via mobile devices (tablet, smart-phone, etc.)

- Better manage the use of energy

- Get real time notifications in order to avoid down times

- Apply predictive maintenance policies

Through the numerous functions that can be integrated into the NET series it is possible to:

-

- Measure and Monitor energy of multiple parts / systems of a building

- Integrate sensors, machine status, alarms and counting signals / impulses

- Make calculations in relation to the pieces produced

- Represent all the quantities on an interactive display

- Log data and events

With Energy Automation in Electrex we mean the interconnection of machines and systems within company processes, with the aim of managing them better thanks to the Energy Automation functions.

In the Electrex devices of the Net series it is possible to implement these Energy Automation functions by ordering the Net upgrade activation codes (PUKs) in order to add to the instruments the “energy PLC” functionality.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 445,000 measuring points and more than 785,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.