Energy audits and energy management are important elements of any energy efficiency strategy. They allow companies to identify their energy-saving potential and hence to reduce their energy consumption significantly. In the EU, for example, Energy Audits are mandatory for large companies, but even small to medium-sized enterprises (SME) can benefit.

While the Energy Management System ensures the long-term implementation of energy efficiency targets and best practices.

Two complementary energy efficiency measures

In energy audits, an internal or external auditor investigates the energy consumption and costs, identifies savings potential and assesses it from a commercial perspective.

Energy management that helps to develop measures, to put them into practice and to monitor them constantly is needed instead in order to integrate the improved efficiency within the company on a permanent basis.

What are energy audits and management systems?

The difference between the energy audit and the EMS lies in the difference between a systematic, one-time procedure and a long-term strategy.

Energy audit: is an assessment of the energy needs and efficiency of a building used to find the inefficiencies.

It is done through an inspection survey and an analysis of the energy use, to identify improvements that need to be made to increase energy efficiency.

This is often the first step in identifying opportunities for energy efficiency.

Energy Management System (EMS): is a set of practical procedures and processes (monitoring, control) for buildings or organizations to achieve best practices relating to energy efficiency, use and consumption, through the setting and delivery of energy targets.

The energy management process starts with an energy audit to find opportunities to improve efficiency, then putting it into action with a number of strategies and then tracking the progress of the made changes.

The EMS is usually aligned with a standard (like ISO 50001) providing a means of validating, a best practice approach and recognising an organization’s commitment to energy performance management and improvement.

Companies need to calculate their total energy consumption, with the audit examining energy use across buildings, transport and industrial activities.

The main technical standards currently used are EN 16247 for the energy audit and EN ISO 50001 for the EMS.

The availability of reliable energy consumption data is of utmost importance to monitor the impact of energy saving measures and behaviors.

Typically, an energy audit closes with the identification of the economic and financial potential of technological solutions to reduce energy consumption and costs.

Today, the Energy audits and EMS are the cornerstones that allow energy efficiency to integrate with the company’s strategic objectives.

They are not just functional tools for the energy manager. They are critical assets being used by the entire organization for managing the challenges of the energy transition.

Contact me to schedule a call! I will be glad to answer any questions you may have.

The Electrex Solutions for Energy Audits and EMS

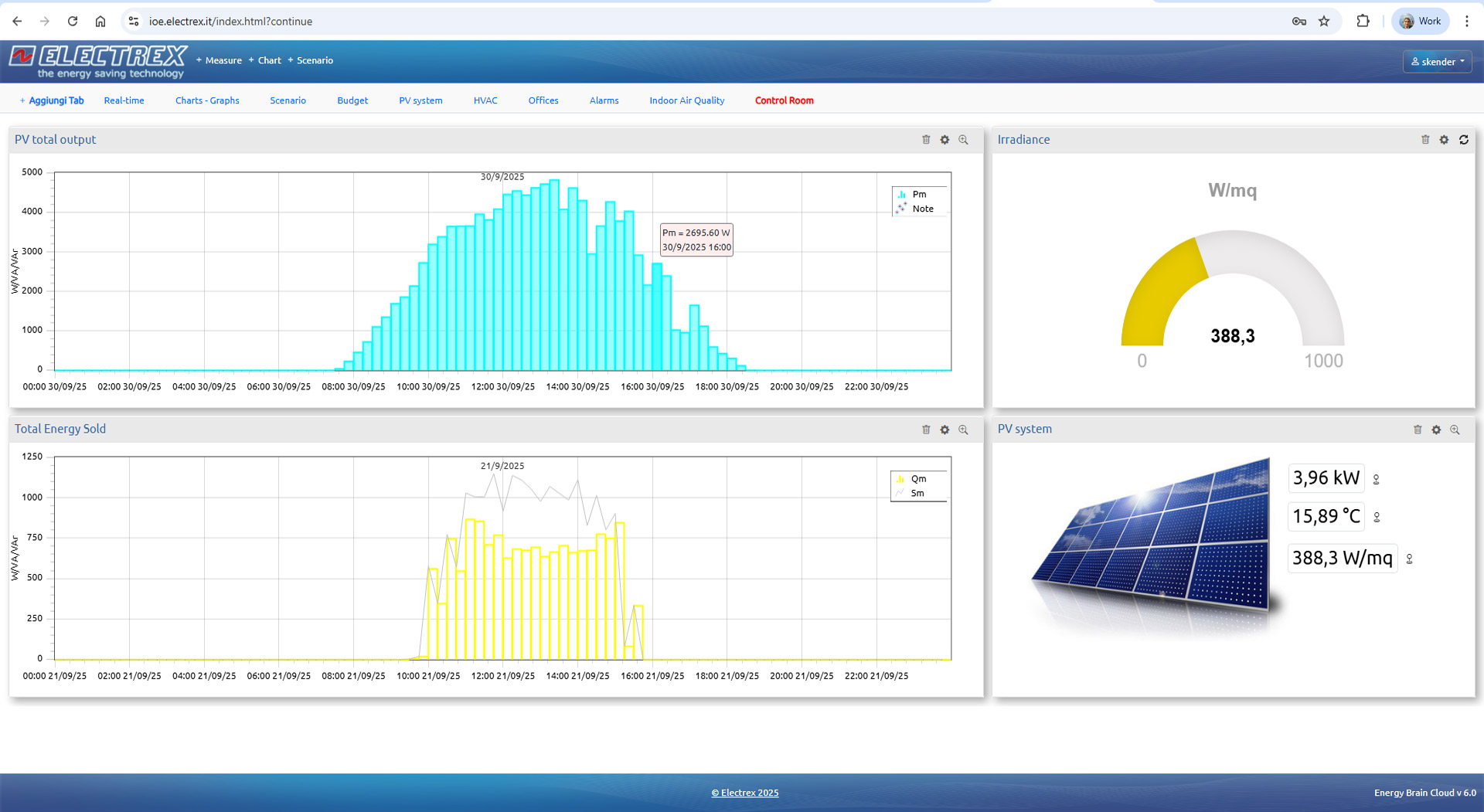

The first step in setting up an energy efficiency project is to understand where, how and when the energy (electricity, gas, etc.) is used.

Energy must be able to be managed and rationalized like any other raw material and to do so, it is necessary to start from continuous monitoring in real time.

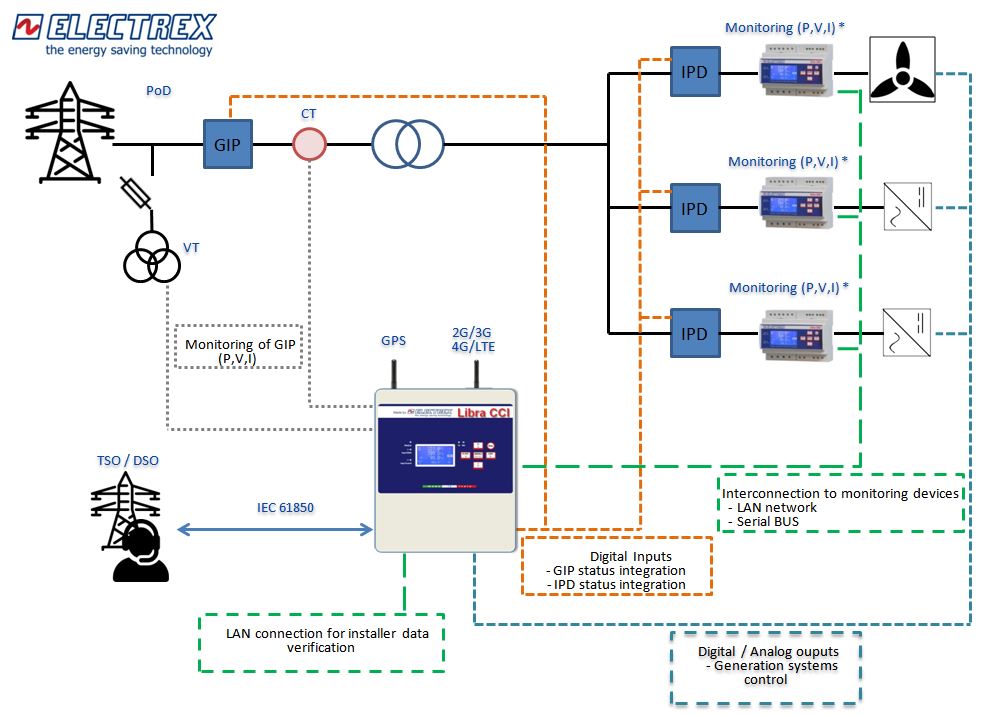

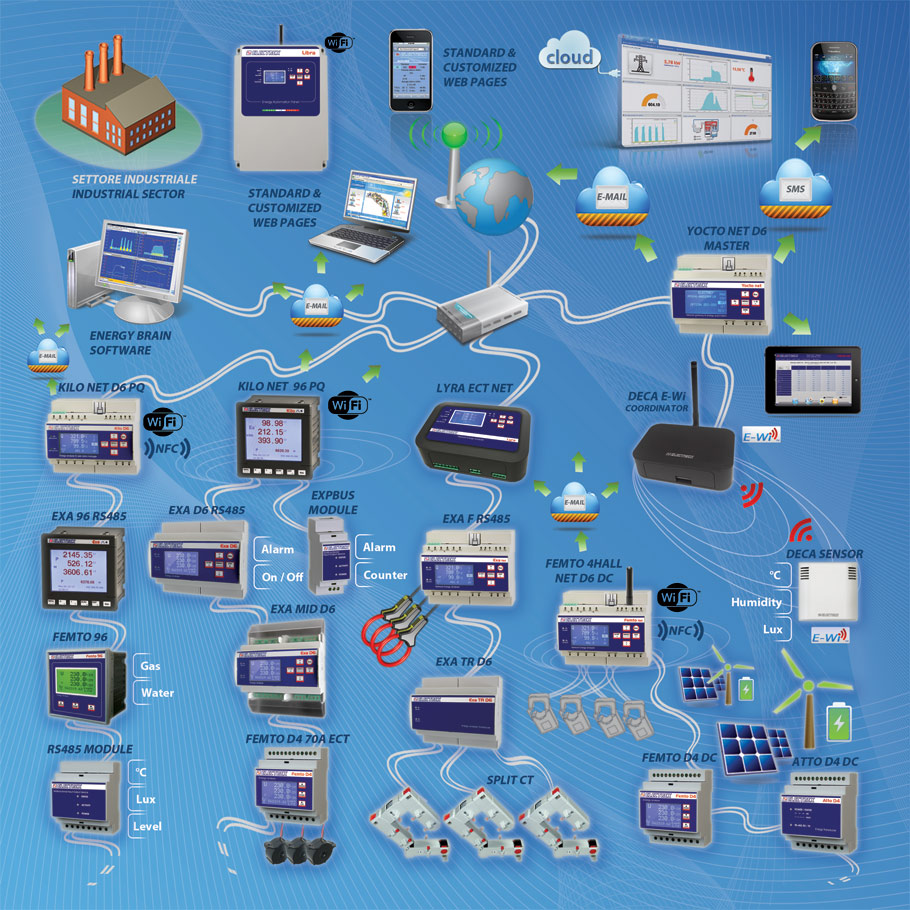

The Electrex Monitoring and Management Solutions are used in the Energy Efficiency and Energy Automation applications, in the industrial, commercial, public buildings and renewable energy systems (PV, Wind, Batteries, etc.) and allow a return on investment in a short time.

They are the ideal solution for energy audits, continuous monitoring (e.g. ISO 50001) and for energy efficiency projects (e.g. White Certificates or Energy Efficiency Certificates, LEED certification).

Open architectures, standards, and interfaces used in the management system play a crucial role in integrating data across buildings, transport and industrial activities.

The Electrex systems are modular and can expand over time thanks to the multiple connection possibilities of the devices: Ethernet, Wi-Fi, RS485, E-Wi, WM-Bus, ExpBus, NFC.

With a single system (with data synchronization) it is possible to monitor and manage all the energy vectors (electricity, gas, water, etc.), the environmental parameters related to them (temperature, humidity, luminosity, CO2, etc.) the process parameters (compressed air, calories, level, status, etc.), and the operating times.

Electrex for many years has embraced this opportunity, opening the way for new applications and services for our partners and customers.

The Electrex Monitoring and Management Solutions make your manufacturing plant or building accessible for the actual and future developments related to Energy Audits and EMS. Our solutions allow you to share energy data with production software or management systems, increasing the benefits of your monitoring and control system.

Some of the concrete actions, applied for years by the users of Electrex solutions, to balance the rising energy costs are:

- Set up intelligent and shared management of data to increase efficiency, operational and decision-making speed

- Calculation of plant yields to reduce energy waste

- Identify and reduce waste thanks to Energy Automation applications

- Manage cost centers to determine and act on the energy impact of each product or activity

- Automatically manage the most convenient energy sources

- Compare energy consumption between different machines or production sites

- Calculate the payback times on investments that have the goal of energy efficiency

- Manage alarms and warnings that allow for immediate controls and interventions

- Monitor and manage all environmental parameters (temperature, humidity, luminosity, CO2, etc.) and process parameters (compressed air, calories, level, status, etc.) which are always closely correlated with energy consumption.

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 465,000 measuring points and more than 820,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.