..

Delivering compressed air in an industrial environment is no small feat — it’s a major cost centre. According to industry insights, energy consumption alone can account for 60-90% of the total lifetime cost of a compressed air system.

That’s why Electrex provides complete solutions to help you monitor, analyze, and optimise your compressed air system — allowing you to reduce energy waste, extend equipment lifetime, and improve process reliability.

Here’s how our systems make that possible:

✅ Continuous monitoring is key

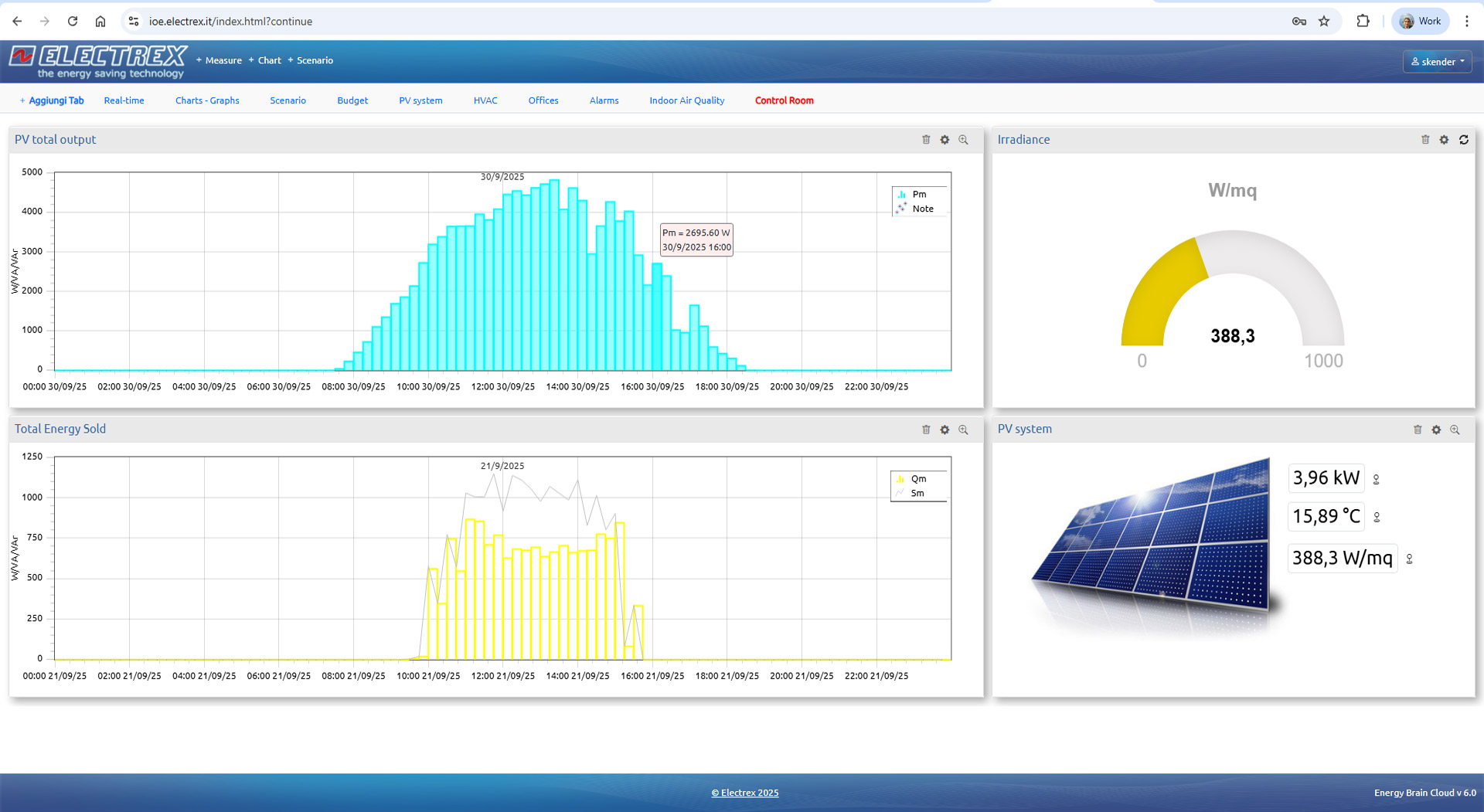

It’s not a one-time activity. You must continuously monitor critical parameters in your compressor room — such as flow, pressure, temperature, dew point — and correlate these against energy consumption and delivered air volume.

✅ Gather and correlate the right data

Many plants already have sensors in place; the missing link is the ability to integrate heterogeneous devices and capture not just electrical power, but process and environmental data too (e.g., analog inputs, digital inputs, PT100 sensors).

✅ Track real KPIs for efficiency

By normalising flow (Qn) and correlating pressure, temperature and energy consumed, you can establish meaningful KPIs that tell you how efficiently your system is producing compressed air.

✅ Enable better cost allocation and comparison

When you have visibility into how much compressed air costs by department, you can automatically generate reports, compare plants globally, and target improvement actions more effectively.

✅ Move from reactive to predictive maintenance

With real-time alarms (pressure, dew point, temperature) and automatic reporting on deviations, you’re no longer stuck in “repair after failure” mode — you’re in “predict & prevent” mode.

👉 If your company is seeking to get more out of its compressed air infrastructure — reduce wasted energy, prevent downtime, and improve operational transparency — let’s connect. I’d be happy to discuss how a monitoring & management solution can unlock savings and performance.

📩 Let’s connect and explore how to integrate the Internet of Energy into your solutions.

#Servitization #DigitalTwin #PredictiveMaintenance #IoT #Electrex #OEM #Industry40 #EnergyManagement #SmartManufacturing #EnergyEfficiency

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 530,000 measuring points and more than 960,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.

Image Attribution: Image by DC Studio on Freepik