..

Across industries, manufacturers and integrators are rethinking their business models.

It’s no longer enough to deliver a great product — customers now expect intelligence, connectivity, and ongoing value.

This evolution is called servitization: turning traditional products into smart, service-oriented solutions that create long-term relationships, recurring revenues, and stronger differentiation.

🔹 Companies are now leveraging digitalization to:

💡 Create continuous value beyond the initial sale

By connecting products through IoT and digital platforms, companies can stay in touch with customers, monitor usage, and offer tailored optimization or maintenance services.

📈 Increase margins through recurring service models

Predictive maintenance, performance analytics, and software upgrades open new revenue streams that go beyond one-time equipment sales.

⚙️ Enhance reliability and customer trust

Monitoring and data analytics make it possible to anticipate faults, reduce downtime, and improve product performance — all key to customer satisfaction and loyalty.

🌍 Promote sustainability and efficiency

Real-time energy and process data help optimize resources, reduce waste, and meet environmental targets — adding both economic and reputational value.

🔹 Electrex: Turning These Trends Into Reality

Electrex systems are designed to make servitization practical and profitable.

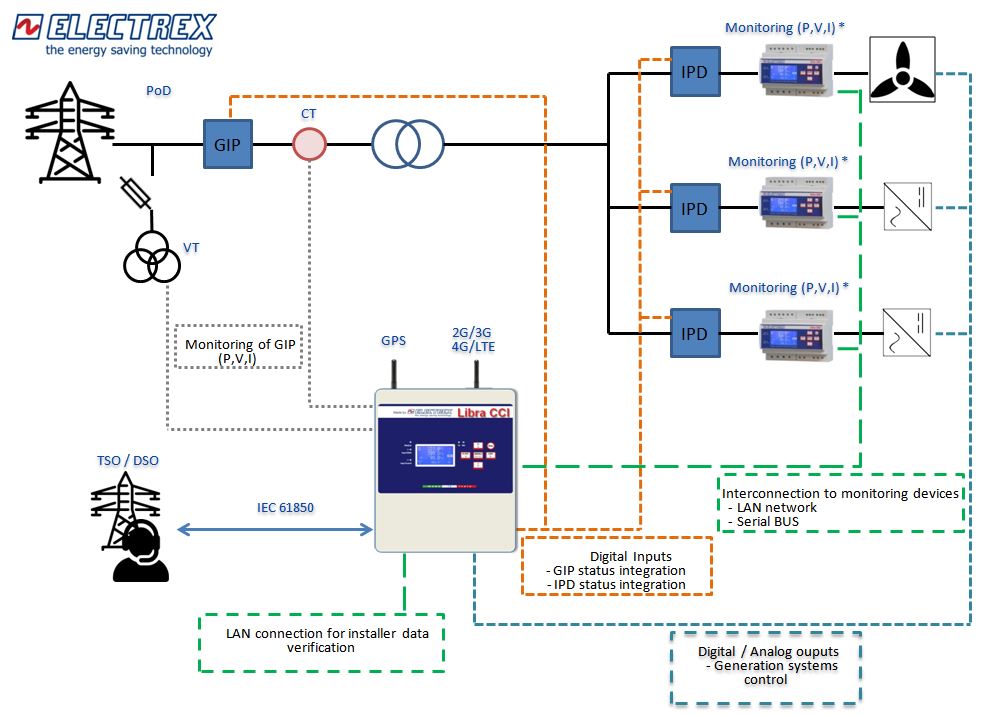

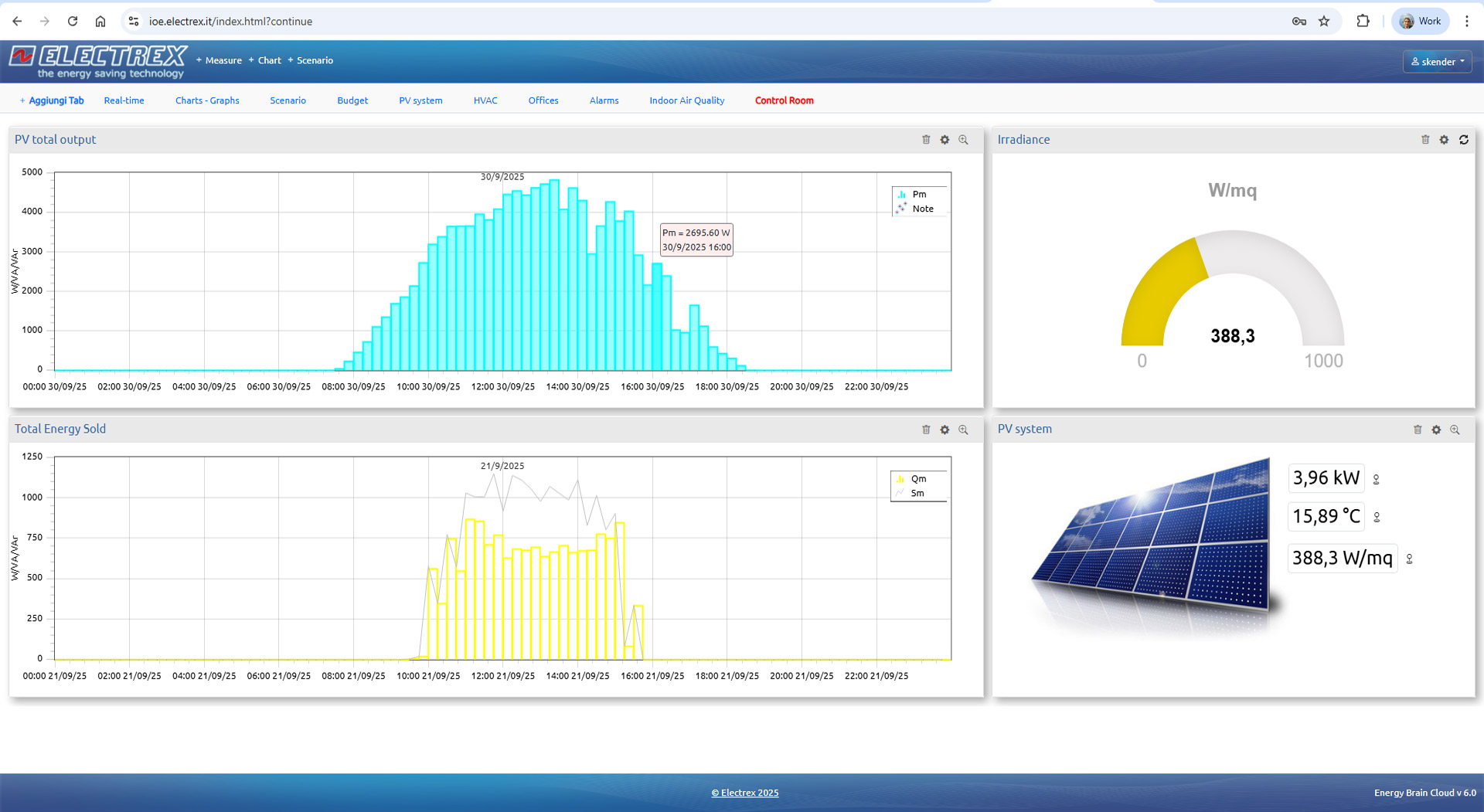

Through our Internet of Energy (IoE) platform, any device, process, or machine can become a Digital Twin — a connected, intelligent replica that collects and analyses real-time energy and process data.

With Electrex, you can:

- Integrate on-site HMI and cloud-based dashboards for complete visibility.

- Enable predictive maintenance and performance optimization.

- Offer value-added digital services alongside your product.

- Build smart, energy-efficient, and data-driven assets ready for Industry 4.0.

Learn more about the Electrex IoE platform →

🔹 A Practical Example

Take the case of a manufacturer of electric ovens for bread and pizza.

By integrating Electrex monitoring systems, the company can:

🍞 Provide the end user with an on-board HMI to control energy use and optimize baking performance.

☁️ Offer a cloud service for remote supervision, efficiency benchmarking, and usage insights.

🔧 Implement predictive maintenance, allowing the manufacturer to detect issues early and propose timely interventions or upgrades.

The result: a simple oven becomes a smart, connected, and service-ready product — generating value for both the user and the manufacturer.

🔹 Ready to Make Your Products Smarter and Your Business More Competitive?

Whether you’re a machine manufacturer, OEM, or system integrator, Electrex helps you transform products into intelligent systems that deliver continuous value.

📩 Let’s connect and explore how to integrate the Internet of Energy into your solutions.

#Servitization #DigitalTwin #PredictiveMaintenance #IoT #Electrex #OEM #Industry40 #EnergyManagement #SmartManufacturing #EnergyEfficiency

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 530,000 measuring points and more than 960,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.

Image Attribution: Image by DC Studio on Freepik