..

Overall Equipment Effectiveness (OEE) is the gold standard for measuring machine performance in manufacturing. It considers availability, performance, and quality defects to provide a holistic picture of how effectively your equipment is producing good parts.

But what if there was a hidden layer to OEE, a way to squeeze even more valuable insights from your existing data? Energy data is the starting point and shall be utilized for the prediction of the overall equipment effectiveness (OEE). Enter Electrex Monitoring Systems and the power of real-time energy data captured through their state-of-the-art IoT devices.

Traditionally, OEE focuses on downtime and production speed. While crucial, this approach can miss subtle signs of inefficiency.

The energy demand of a machine is a state variable that is rather simple to acquire and potentially reflects nicely and in real time what is currently happening.

Here’s where energy data, captured by Electrex’s comprehensive monitoring solutions, steps in.

By analyzing a machine’s energy consumption patterns, you can gain valuable insights into its health and performance, often before traditional OEE metrics pick up on an issue.

Why Electrex Monitoring Systems are Perfect for Unlocking the Power of Energy Data in OEE

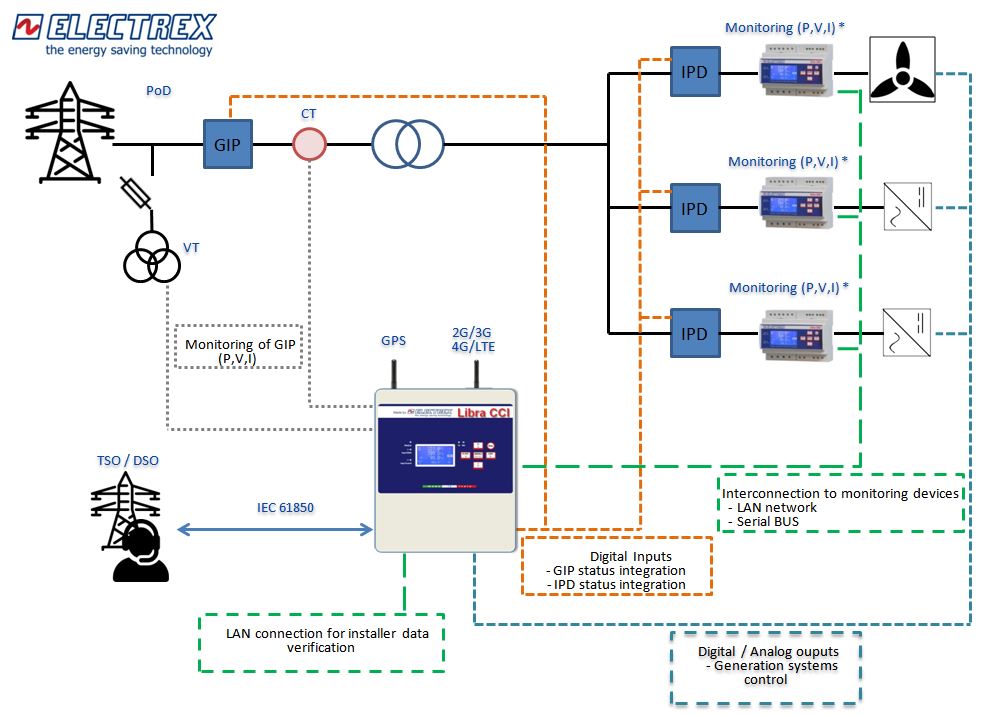

- Real-time Data Acquisition: Electrex systems provide continuous monitoring, capturing energy consumption fluctuations in real-time. This allows for immediate identification of deviations from normal operating patterns, enabling proactive maintenance.

- Modular and Scalable: Electrex’s modular design caters to various needs. You can start with monitoring a single machine and seamlessly expand to encompass your entire facility as needed. Multiple connectivity options (Wi-Fi, RS485, etc.) ensure easy integration into existing infrastructure.

- Holistic Monitoring: Electrex goes beyond just energy. The system tracks environmental parameters (temperature, humidity) and process parameters (compressed air, pressure) that can influence both machine performance and energy use. This comprehensive data allows for a more nuanced understanding of machine health.

- Automated Actions: Electrex empowers automation. The system can trigger actions based on pre-defined thresholds. For instance, it can automatically shut down idling equipment or adjust settings to optimize energy use, all contributing to improved OEE.

Unmatched Capabilities for Advanced OEE Optimization

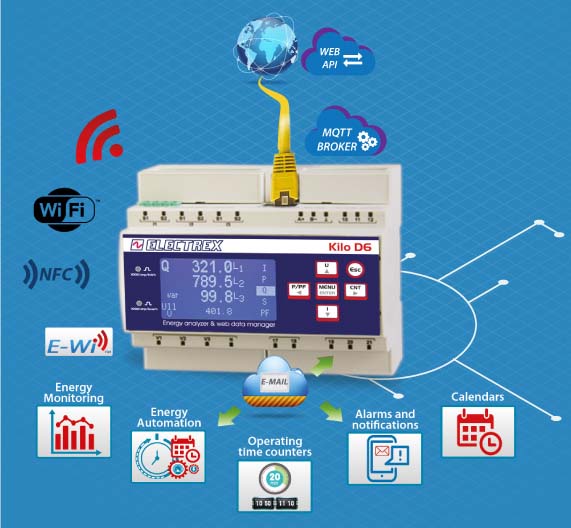

Electrex takes machine monitoring to the next level with its feature-rich IoT devices:

- Flexible Data Sharing: Electrex devices seamlessly share data via industry-standard protocols like WEB APIs and MQTT, enabling effortless integration with your existing data infrastructure and analytics platforms.

- Embedded Intelligence: Select Electrex devices boast an embedded PLC with a built-in Ladder programming editor. This allows for on-device logic and control, further streamlining automation and optimizing machine performance based on real-time data.

- Precision Timing: NTP server synchronization ensures all devices within the Electrex system maintain perfect time accuracy. This is crucial for precise data analysis and ensuring all events and alarms are correctly correlated.

- Granular Operating Time Monitoring: Electrex devices utilize partial counters triggered by programmable alarms and events based on real-time measurements (power, voltage, current, etc.). This allows for highly granular tracking of operating time under specific conditions, providing invaluable insights into machine behavior and potential inefficiencies.

Unlocking the Potential: Integrating Electrex Data into OEE

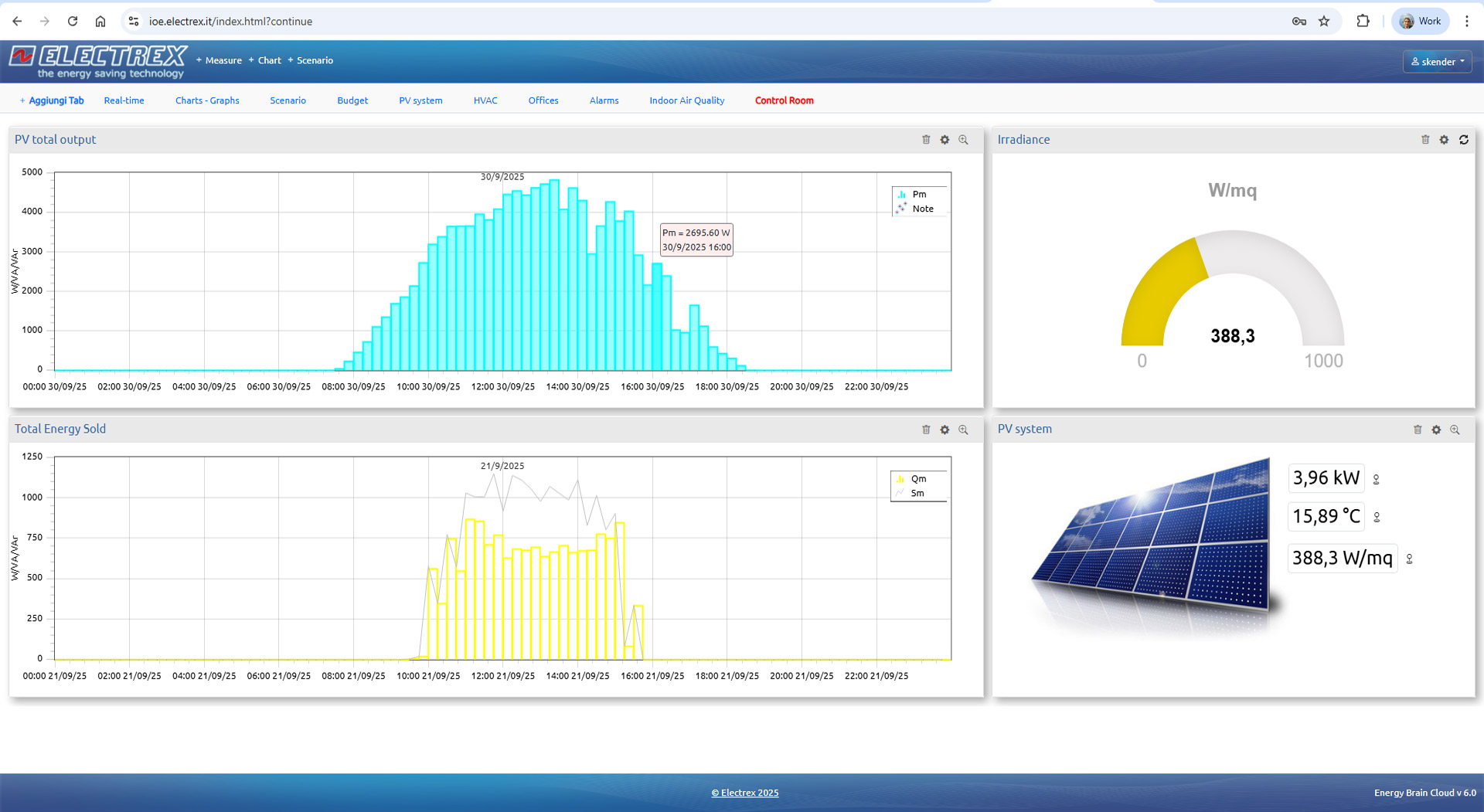

While energy data isn’t a formal part of the OEE calculation, it acts as a powerful companion metric. Here’s how to leverage Electrex data for OEE optimization:

- Establish Benchmarks: Use Electrex to track a machine’s typical energy consumption patterns during different operating states. Deviations become red flags for potential problems.

- Correlate with OEE Data: Look for correlations between energy consumption changes identified by Electrex and dips in OEE metrics like performance or availability. This can help pinpoint the root cause of issues and prioritize maintenance activities.

- Predictive Maintenance: Integrate Electrex data with existing predictive maintenance programs. This allows you to anticipate equipment failures based on changing energy use patterns, further optimizing maintenance schedules and maximizing equipment uptime.

The Takeaway: Electrex – Unlocking the True Potential of OEE

Electrex Monitoring Systems provide a comprehensive solution for capturing the valuable energy data that, when combined with OEE, paints a more comprehensive picture of machine health and performance. By harnessing the power of Electrex’s real-time data acquisition, modular design, and automated functionalities, you gain a proactive edge in identifying and addressing inefficiencies before they impact production. This translates to improved OEE, reduced downtime, and ultimately, a more efficient and profitable manufacturing operation.

Ready to take your OEE to the next level with Electrex Monitoring Systems?

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 505,000 measuring points and more than 910,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.