Continuous measurement and monitoring of reactive power are necessary to determine the correct compensation system and to monitor it to ensure that it is providing the required level of compensation. This helps to reduce energy costs, maintain power quality, and improve the efficiency of electrical systems.

What is reactive energy?

Reactive energy, also known as reactive power, is a type of electrical energy that is used to maintain the electromagnetic fields in alternating current (AC) circuits. It is called reactive energy because it does not perform useful work directly, but it is necessary for the operation of many electrical devices, such as motors, transformers, and fluorescent lights.

Reactive energy is produced and consumed by electrical devices that have inductive or capacitive components. Inductive components store energy in a magnetic field, while capacitive components store energy in an electric field. When the current flows through these components, the energy is transferred back and forth between the magnetic and electric fields.

This transfer of energy is called reactive power, and it is measured in units of Volt-Amperes Reactive (VAR).

Reactive energy is important to consider when designing and operating electrical systems because it can have a significant impact on the efficiency and quality of the power supply.

Types of reactive powers:

- Inductive reactive power: Motors, transformers and control gears are inductive loads.

- Capacitive reactive power: Capacitors in electronic equipment and long cables are capacitive loads.

- Harmonic reactive power: rectifiers (laptop power supplies, servers) and inverters in modern UPS and frequency inverters. The harmonic distortion creates extra power that is called harmonic reactive power (Qh).

Reactive power is not converted into useful energy and can consist of inductive, capacitive and harmonic reactive power or a combination of these.

Which are the consequences of a too high reactive power?

A high level of reactive power can have several consequences for an electrical system, including:

Penalties and claims: A high level of reactive power can lead to a fine from the grid operator. Too much reactive power leads to extra load for the operator. While in case of harmonic reactive power, the grid operator can file a claim if limits are surpassed.

Reduced power factor: The power factor is a measure of the efficiency of an electrical system. A high level of reactive power can reduce the power factor, which means that the system is less efficient and more energy is required to deliver the same amount of power.

Voltage drops: Reactive power causes voltage drops in electrical systems. This can lead to decreased efficiency and reliability of the electrical devices that are connected to the system.

Overheating: Reactive power can cause electrical devices to overheat, which can lead to damage and reduced lifespan of the devices.

Increased energy costs: High levels of reactive power can result in increased energy costs due to lower power factor and increased energy consumption.

Reduced system capacity: A high level of reactive power can reduce the capacity of an electrical system to deliver power to connected devices.

Contact me to schedule a call! I will be glad to answer any questions you may have.

Why continuous measurement and monitoring is necessary to determine the correct compensation system and to monitor it.

It is important to manage and compensate for reactive power because it can lead to increased energy costs, reduced power quality, and decreased efficiency of electrical systems.

electrical systems.

Continuous measurement and monitoring of reactive power is necessary to determine the correct compensation system and to monitor it for a few reasons:

Accurate Measurement: Reactive power is difficult to measure accurately, and it can vary over time. Continuous measurement and monitoring help ensure that the compensation system is accurately measuring reactive power and adjusting for changes.

Proper Compensation: Reactive power compensation systems need to be properly sized and adjusted to match the requirements of the electrical system. Continuous measurement and monitoring can help ensure that the compensation system is providing the correct level of compensation.

Preventive Maintenance: Electrical systems can change over time due to aging, wear and tear, and other factors. Continuous measurement and monitoring can help identify changes in the electrical system that may affect the performance of the compensation system. This allows for preventive maintenance to be performed before problems occur.

Cost Optimization: Reactive power compensation can be expensive. Continuous measurement and monitoring can help optimize the use of compensation systems to reduce energy costs while maintaining power quality and efficiency.

Determining the correct compensation techniques and capacity without being based on measurement data can be expensive and dangerous.

For example, using capacitor banks in systems with too many harmonics can lead to resonances due to the interaction of the harmonic currents and the capacitors. Therefore it will lead to overloading of the capacitor bank which results in very dangerous consequences

The monitoring activity should continue also after the compensation system is active in order to support the maintenance activity and advise on changes to the installation.

The Electrex Monitoring, Management and Automation Solutions

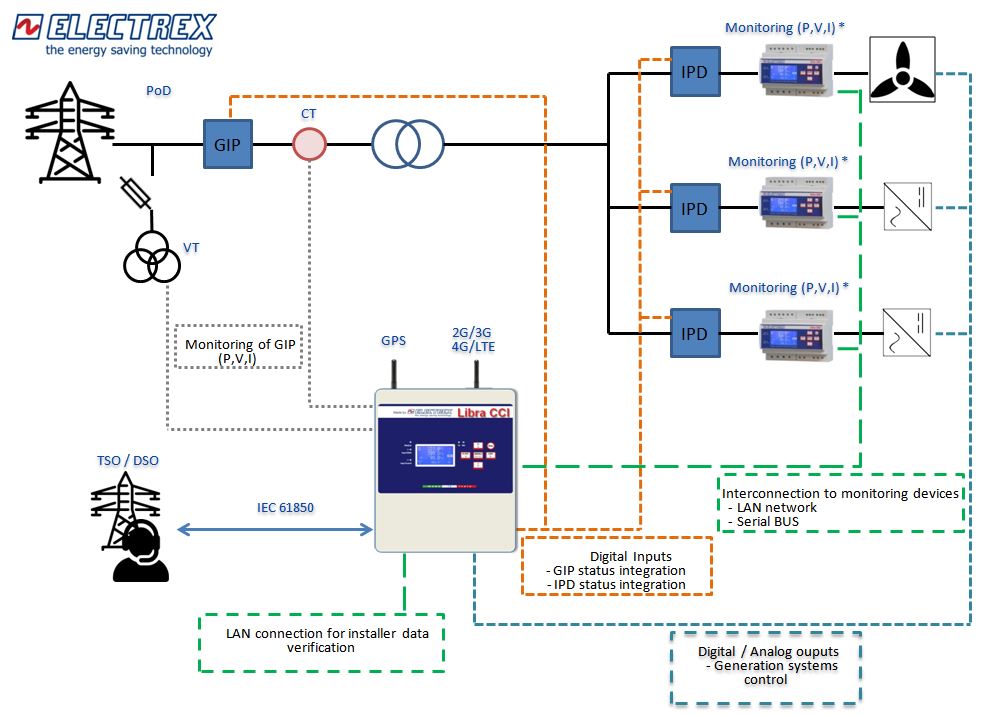

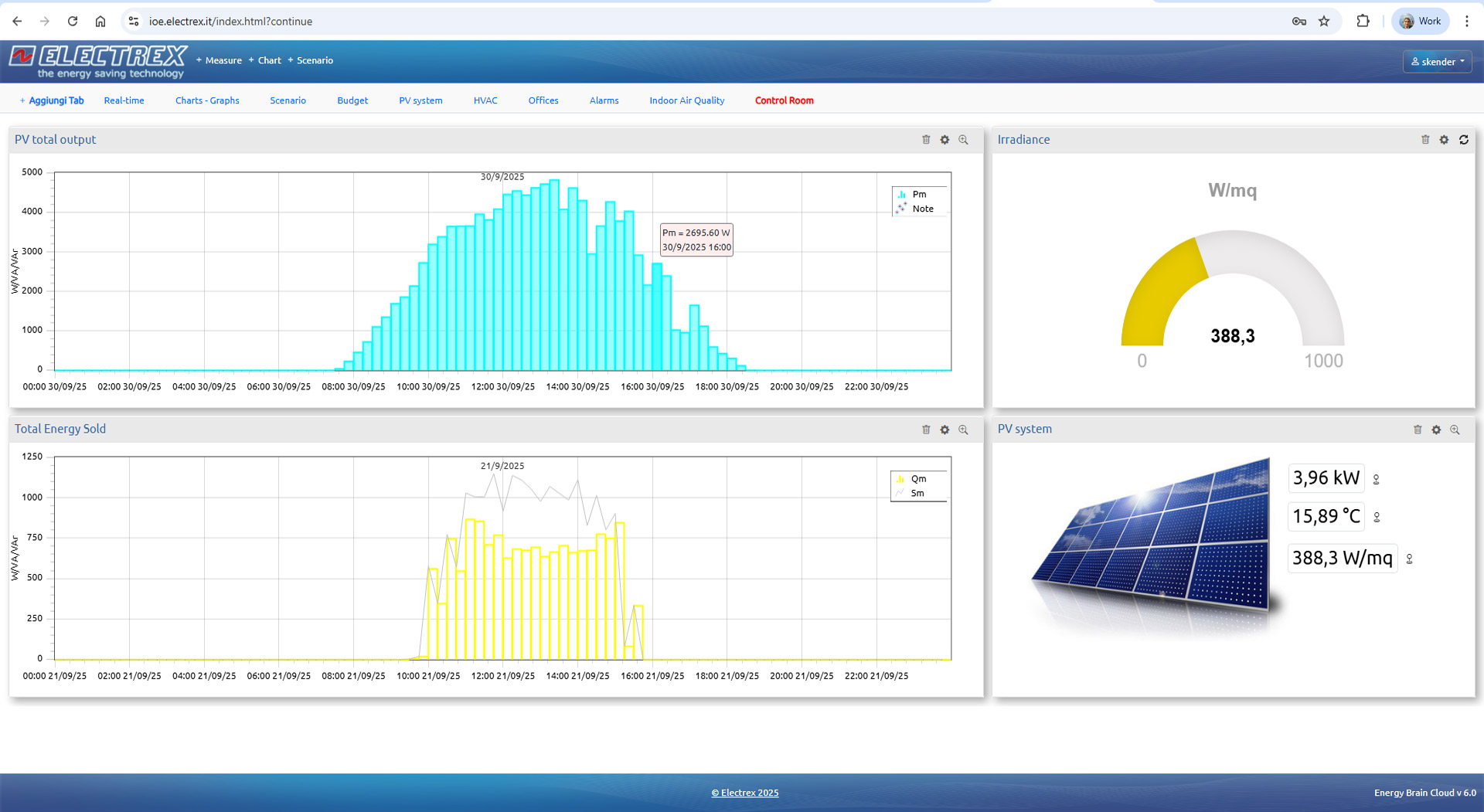

The Electrex Monitoring and Management Solutions are used in the Energy Efficiency and Energy Automation applications, in the industrial, commercial/public buildings and renewable energy systems (PV, Wind, Batteries, etc.) and allow a return on investment in a short time.

The Electrex systems allow for proactive management of reactive power and can help prevent problems before they occur.

As a result of the continuous analyses, the reactive energy can be constantly zeroed or drastically reduced by exploiting the energy automation functions of the Electrex solutions.

On the Electrex Net series (Kilo net, Exa net, Femto ECT net, Yocto net, Libra net and Lyra net) it is possible to implement energy automation and power quality monitoring functions also remotely, inserting an activation code via the embedded web pages.

It is possible therefore to activate an embedded “energy PLC” functionality on the instruments allowing to create energy automation applications within the same energy analyzer.

If you already have an Electrex network, contact us to verify that your equipment has the necessary functions and is correctly configured for reactive energy related applications.

Electrex offers a range of monitoring and control solutions that can be customized to meet the specific needs of the electrical system. This means that the solutions can be tailored to the size and complexity of the system, as well as the specific goals of the customer.

In addition the Electrex solutions can be easily integrated with existing electrical systems, making it easy to add new functionality without requiring major changes to the system.

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 465,000 measuring points and more than 820,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.