..

The Challenge of Industry 5.0

The Industry 5.0 transition plan emphasizes the need for companies to embrace both digitalization and energy efficiency. This means monitoring energy consumption to streamline production and measure the savings achieved through digital technologies.

The Importance of Measurement

The success of an Industry 5.0 project hinges on a company’s ability to accurately measure its energy use and demonstrate the resulting improvements in energy efficiency.

The Lyra ECT Net Energy Analyzer & Web Data Manager Solution

Our Lyra ECT Net is an energy monitoring solution designed specifically for Industry 5.0 machines. It offers several key advantages:

- Quick and Easy Installation: The Lyra ECT Net is designed for fast, non-invasive installation, making it ideal for situations where space in electrical panels (including those on machines) is limited.

- Versatility: The Lyra ECT Net is a microprocessor-based Energy Analyzer & Web Data Manager suitable for various applications in industrial, commercial, public, and residential sectors. Its functional and user-friendly design makes it easy to set up and use.

- Flexible Mounting: The elegant and functional case with Plug-and-Play connectors allows for wall mounting or installation within electrical panels, including those on machines, even when space on a DIN rail is unavailable.

- High Precision: The Lyra ECT Net boasts a high precision Class of 0.5S for active energy across the entire measurement system (analyzer plus current transformers). It achieves this accuracy by continuously sampling voltage and current waveforms at high resolution, ensuring reliable measurements even for rapidly changing loads (for example spot welding).

- Comprehensive Harmonics Analysis: The Lyra ECT Net measures single harmonics up to the 51st order and provides detailed power quality data (PQ version).

- Multiple Connectivity Options: The Lyra ECT Net offers RS485 master/slave and Ethernet ports, with a Wi-Fi version available for wireless connectivity.

- Large Memory Capacity: The 128MB memory allows for implementing various functionalities through PUK activation codes. Additionally, the architecture enables remote firmware updates.

- Power Quality Management (PQ Version): The PQ version goes beyond basic energy monitoring by providing functions that comply with EN 50160 (peaks, dips, interruptions, harmonics) and EN 61000-4-30 Class S standards. It offers features such as detailed event graphics, tables, timelines, customizable measurement campaigns, and programmable sampling frequencies.

- Web Server Functionality: The Lyra ECT Net functions as a web server for managing itself and any instruments connected to the RS485 subnet, including devices from other manufacturers.

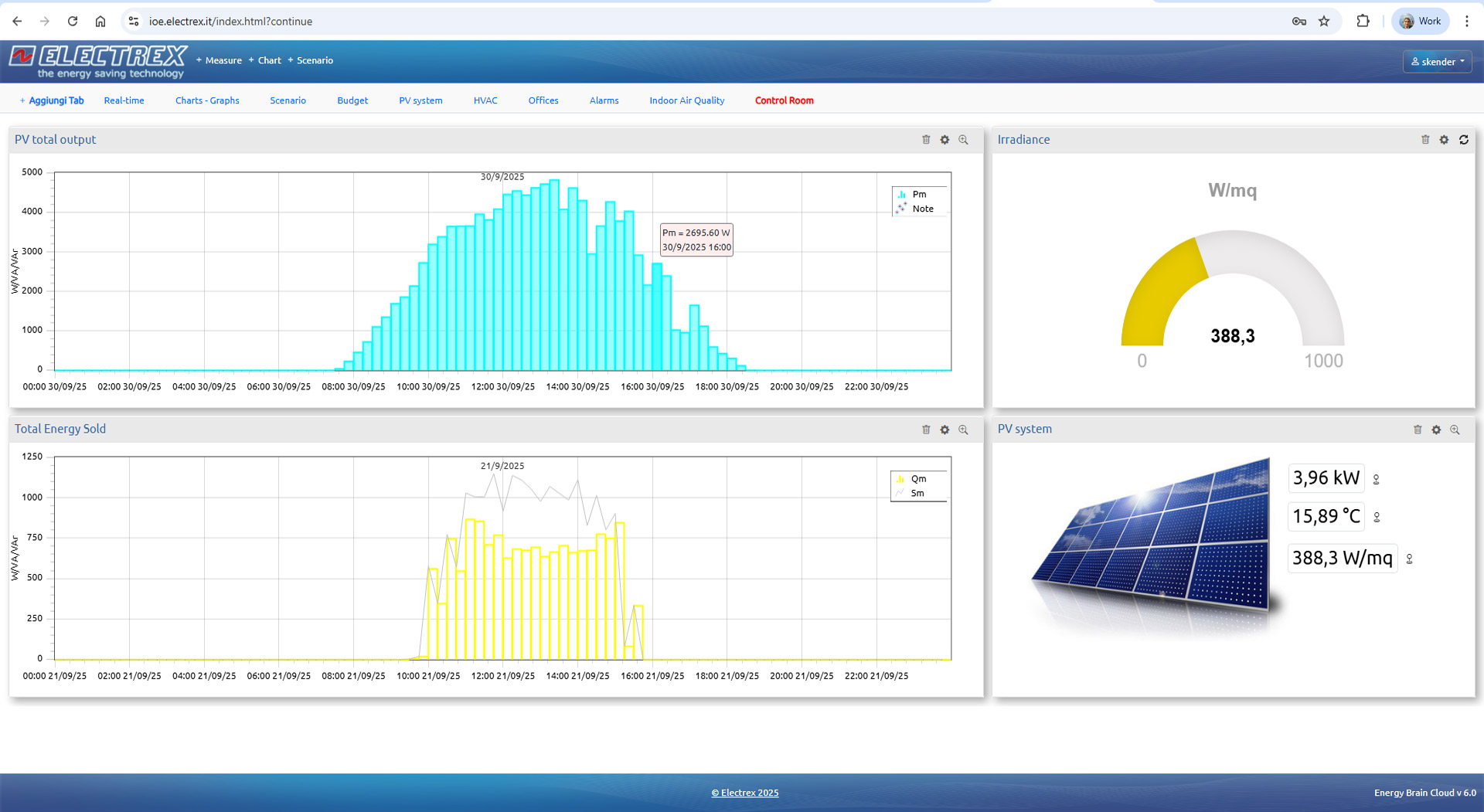

- Scalable Monitoring System: The Lyra ECT Net serves as a starting point for a comprehensive energy efficiency monitoring system. It allows for the measurement and management of various parameters, including energy (electricity, gas, water), environment (temperature, humidity, light, CO2), and process data. It also features a built-in web server, FTP server, and RS485 master communication for connecting with other devices.

- Wireless Convenience (Wi-Fi Version): The Wi-Fi version enables data management and visualization using any Wi-Fi-enabled device with a web browser, such as a PC, smartphone, or tablet, within an existing Wi-Fi network.

Contact me to schedule a call! I will be glad to answer any questions you may have.

About us

Since 1993 Electrex designs, develops, manufactures and markets, Made in Italy, instruments and software for energy management and control.

The Electrex solutions are used in the Energy Efficiency and Energy Automation applications, for the industrial, commercial, public, civil, and renewable energy sectors allowing a rapid return on investment.

The solutions provided up to now allow the management of over 505,000 measuring points and more than 910,000 points are controlled via Energy Automation applications.

Electrex, one of the first companies to operate in these sectors, has acquired over the years a considerable experience and competence that few other companies can claim to have. With over 40% of the staff dedicated to R & D, we demonstrate our strong commitment to innovation and continuous improvement in order to anticipate the needs of our customers.